What is an Automatic Packaging Machine and How Does It Work?

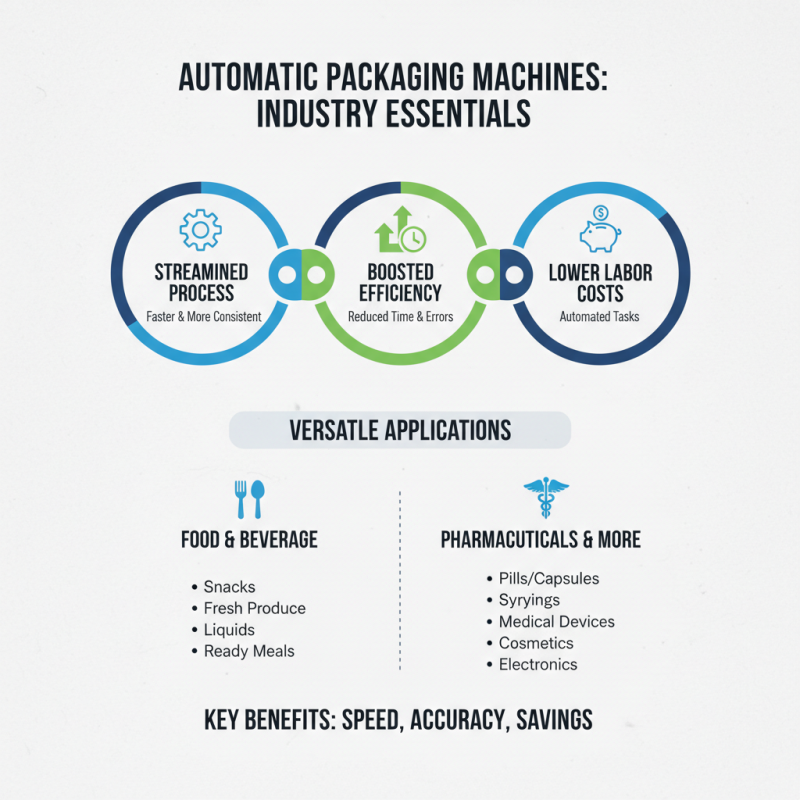

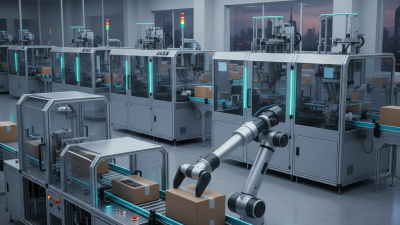

An automatic packaging machine plays a crucial role in modern manufacturing. It streamlines the packaging process, increasing efficiency and reducing labor costs. This technology is widely used across various industries, improving product delivery and presentation.

These machines can handle different types of packaging, from bottles to boxes. They employ advanced mechanisms to accurately package items at high speeds. The precision of an automatic packaging machine ensures that products are sealed securely and efficiently.

However, users should remember that these machines require regular maintenance. Malfunctions can lead to downtime, affecting production schedules. It's essential to train staff properly to ensure smooth operation. The integration of such technology can be rewarding but might pose challenges too. Careful consideration is needed to optimize their use.

What is an Automatic Packaging Machine?

An automatic packaging machine is a crucial component in modern manufacturing. It streamlines the packaging process, increasing efficiency and consistency. This equipment can handle various products, from food items to pharmaceuticals. According to industry reports, the global packaging machinery market is projected to reach $50 billion by 2026. This growth indicates its significance across multiple sectors.

These machines operate by automating tasks such as filling, sealing, and labeling. They can significantly reduce labor costs, as one machine can perform tasks usually requiring multiple workers. Data suggests that automation can improve production speed by up to 50%. However, it’s essential to consider potential drawbacks. High initial investment costs can be a barrier for smaller businesses. Additionally, reliance on automation may lead to a loss of manual skills among workers.

While automatic packaging machines boost productivity, they also require regular maintenance. Machinery can malfunction, leading to production delays. It’s vital for companies to remain vigilant about performance. Training staff on machine operation is equally important to mitigate risks. Balancing efficiency with human expertise presents an ongoing challenge in the industry.

Key Components of Automatic Packaging Machines

Automatic packaging machines play a vital role in modern manufacturing. They enhance efficiency and reduce manual labor. Understanding their key components is essential for optimizing their performance.

The main components include the conveyor belt, filling system, and sealing mechanism. The conveyor belt transports products seamlessly through the packaging process. It must be reliable and adjustable for various product sizes. The filling system accurately dispenses the correct amount of product, ensuring quality control. The sealing mechanism ensures packages are securely closed; improper seals can lead to product spoilage.

Sensors and control systems are also significant. Sensors monitor the machine’s operation and detect any issues. Control systems allow operators to adjust settings quickly. Often, operators can overlook minor faults until they escalate. Regular maintenance can help prevent these oversights. In less optimal setups, even a small malfunction can lead to major delays. Understanding these components allows for better troubleshooting and improved productivity.

How Automatic Packaging Machines Operate

Automatic packaging machines are essential for many industries. They streamline the packaging process, improving efficiency and reducing labor costs. These machines can handle various products, from food items to pharmaceuticals.

These machines operate through a series of steps. The process starts with product feeding. Products are placed on conveyor belts, where sensors ensure correct placement. Then, the machine forms, fills, and seals packages. Advanced technologies like vision systems monitor quality, detecting any packaging defects. According to a report by MarketsandMarkets, the automatic packaging machinery market is projected to reach $54.86 billion by 2026. This growth indicates increasing reliance on automation in packaging.

Tips: Regular maintenance of packaging machines can prevent unexpected downtime. Training staff on machine operation improves efficiency and reduces errors. Remember, the choice of packaging material plays a crucial role in the final product quality. Not all materials suit every product, so consider compatibility carefully. Experimenting with different packaging methods may yield better results.

Advantages of Using Automatic Packaging Machines

Automatic packaging machines are becoming essential in various industries. They offer many advantages that enhance productivity and efficiency. One major benefit is speed. These machines can package products much faster than manual methods. This can drastically reduce labor costs and increase output.

Another advantage is consistency. Automatic machines provide uniform packaging, minimizing variations. This leads to better brand image and customer satisfaction. Products are less likely to be damaged during the packaging process, ensuring they reach consumers in perfect condition.

Tips: When choosing an automatic packaging machine, consider your product size and shape. Not all machines fit every product type. Regular maintenance is also crucial. A well-maintained machine performs better and lasts longer. Ensure your staff is trained properly to operate these machines. Inadequate training can lead to inefficiencies and errors.

While there are numerous benefits, challenges exist. Initial costs can be high, and the learning curve may be steep. Companies should evaluate their needs carefully before investing. Balancing automation with skilled labor can bring the best results.

Applications of Automatic Packaging Machines in Various Industries

Automatic packaging machines are transforming various industries. In food and beverage, these machines ensure products are sealed properly. This improves shelf life and hygiene. According to a recent market report, the global food packaging market is expected to reach $500 billion by 2025. The need for efficiency is driving this growth.

Pharmaceutical companies also rely heavily on automatic packaging. Precise dosage and tamper-proof seals are critical. A report indicated that the pharmaceutical packaging market is projected to grow at a CAGR of 7% from 2023 to 2030. Automating this process reduces human error and boosts production speed. However, some businesses struggle with adapting to new technologies.

In the cosmetics industry, automatic packaging machines can handle complex designs. With rising consumer demand, brands seek innovative packaging. Reports show a correlation between attractive packaging and higher sales. Yet, balancing sustainability with automation remains a challenge. Companies need to rethink their strategies to meet eco-friendly goals while automating packing processes effectively.

Related Posts

-

How to Choose the Right Automatic Packaging Machine for Your Business Needs

-

The Ultimate Guide to Choosing the Best Package Machine in 2025

-

Top 10 Bagging Machines for Efficient Packaging Solutions and Cost Savings

-

Top 10 Benefits of Using an Automated Packaging Machine for Your Business

-

How to Choose the Right Box Packing Machine for Your Business Needs

-

Why Choose an Automatic Packing Machine for Your Business?

A & B Packing Equipment

A&B has become the leader in fresh packing and cleaning equipment for fruits and vegetables worldwide. We have achieved this by relentlessly working to produce new and innovative ideas, along with the best customer service on Earth combined with hard working, dedicated, loyal employees and the latest industrial manufacturing techniques. We are now proud to say that we manufacture The Fulcrum Fresh Harvester, this is a one of a kind Berry Harvester that was specifically designed to handle fresh pick blueberries.

Contact Information

732 W. Saint Joseph Street

Lawrence, MI 49064

Phone: 269-539-4700 Fax: 269-539-4705

sale@industrialpackagingmachines.com