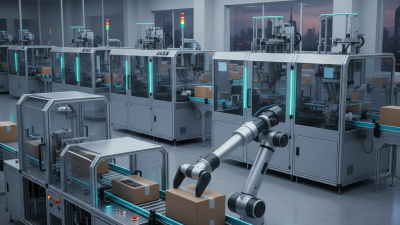

Why Choose an Automatic Packing Machine for Your Business?

In today’s fast-paced market, efficiency is key. Businesses are constantly seeking ways to enhance productivity. An automatic packing machine can be a game-changer for many industries. John Doe, a renowned expert in packaging technology, states, “Investing in an automatic packing machine boosts both speed and accuracy.” This quote emphasizes the growing importance of automation in packing processes.

Implementing an automatic packing machine can streamline operations. It reduces manual labor and minimizes errors. For instance, unlike manual packing, machines can perform repetitive tasks consistently without fatigue. This leads to faster turnaround times and improved product output. However, businesses must also consider the initial investment cost and maintenance.

Transitioning to an automatic packing machine isn't always straightforward. Companies may face challenges in training staff or integrating new systems. Continuous evaluation of the process is crucial. Moreover, not every product is suitable for automation. Identifying the right fit is essential for maximizing returns.

Understanding the Basics of Automatic Packing Machines

Automatic packing machines play a vital role in streamlining business operations. These machines help to enhance efficiency and save time. They can handle various types of products, from small items to larger packages. The versatility makes them appealing to many industries.

Understanding the basics of automatic packing machines is crucial. They operate with user-friendly interfaces, allowing easy adjustment for different products. Some machines offer customization features to meet specific needs. However, not all businesses may benefit equally from this technology. For smaller operations, the initial investment can feel overwhelming. Balancing cost against potential efficiency gains is essential.

Failure to properly train staff on these machines can lead to errors. Misuse can result in product damage or wasted materials. Regular maintenance is necessary to keep machines running smoothly. Overall, while automatic packing machines promise efficiency, they require careful consideration and planning for effective implementation.

Key Advantages of Using Automatic Packing Machines

Choosing an automatic packing machine can significantly streamline your business operations. One of the key advantages is efficiency. These machines can pack products at a high speed. This reduces the time taken for each packing cycle. Imagine saving hours every day, allowing your team to focus on other tasks.

Another benefit is consistency in packaging. Automatic machines ensure that every package meets the same standards. This uniformity enhances the professional look of your products. Customers appreciate well-packaged items. Discrepancies can affect their experience and trust.

Moreover, automatic packing can help reduce labor costs. It minimizes the need for manual labor, which can be expensive. However, it does require a learning curve for your team. Regular maintenance is crucial for optimal performance. It’s important to plan for potential downtime. Balancing automation and human oversight is key to success.

Factors to Consider When Choosing an Automatic Packing Machine

When selecting an automatic packing machine, several factors come into play. The size of your products is crucial. Machines need to accommodate your items effectively. For example, packing small bottles differs significantly from larger boxes. A misfit can lead to wasted materials and increased costs.

Consider the packing speed as well. High-speed machines can boost productivity, but they may not suit small operations. If you have lower volumes, a slower machine could be more efficient. Ensure that the machine matches your output needs without compromising quality.

Tips: Do a test run before making a purchase. This allows you to see the machine in action. Look for adjustment features. They enable you to switch between products easily. Maintenance is another point to ponder. Some machines are easier to clean than others. An overly complex system can lead to work disruptions and frustration over time. Reflect on your long-term needs, not just short-term gains.

Reasons to Choose an Automatic Packing Machine

Common Applications of Automatic Packing Machines in Various Industries

Automatic packing machines are transforming various industries. They enhance efficiency in food processing, pharmaceuticals, and consumer goods. In the food industry, these machines seal and pack items quickly. This helps maintain freshness. For instance, snack packaging often requires speed and precision. Automatic machines meet these demands effortlessly.

In pharmaceuticals, packaging is crucial for safety. Automatic machines ensure that medications are sealed properly. This reduces human error significantly. It’s essential for maintaining compliance with health regulations. Many companies are hesitant to invest. However, the quality assurance gained is invaluable.

Tip:

Consider the machine's adaptability to different products. Not all machines fit every need.

In the consumer goods sector, automatic machines handle various items. They pack everything from cosmetics to electronics. This diversity is beneficial for businesses looking to expand. Yet, it’s vital to evaluate the costs. Sometimes, initial fees can be overwhelming. Assess long-term savings before making a decision.

Tip:

Always review machine maintenance requirements. Regular upkeep is necessary for efficiency.

Cost-Benefit Analysis of Implementing Automatic Packing Machines

Automatic packing machines can significantly impact your business's efficiency. They streamline operations, reducing labor costs. For instance, a machine can pack products in a fraction of the time it takes humans. This speed results in higher output. However, initial installation costs can seem daunting. It's crucial to analyze your budget carefully.

Consider the long-term savings. While there is an upfront investment, the reduction in labor and increased accuracy can balance this over time. Mistakes in packing can lead to product damage and customer dissatisfaction. Machines minimize these issues. Additionally, there's less need for overtime pay, which can inflate expenses.

Yet, the transition to automation isn't always smooth. Staff may need retraining, leading to temporary disruptions. Some workers might resist changing their routine. Keeping this in mind is vital. The balance between cost and benefit isn't always clear. Reflecting on these factors will help you make informed decisions.

Related Posts

-

How to Choose the Right Automatic Packaging Machine for Your Business Needs

-

Top Automatic Packing Machines to Look for in 2025 for Efficient Packaging

-

How to Choose the Right Box Packing Machine for Your Business Needs

-

Top 10 Benefits of Using an Automated Packaging Machine for Your Business

-

How to Choose the Best Packing Equipment for Your Business Needs

-

2025 Top Trends in Fresh Harvester Technology and Innovations

A & B Packing Equipment

A&B has become the leader in fresh packing and cleaning equipment for fruits and vegetables worldwide. We have achieved this by relentlessly working to produce new and innovative ideas, along with the best customer service on Earth combined with hard working, dedicated, loyal employees and the latest industrial manufacturing techniques. We are now proud to say that we manufacture The Fulcrum Fresh Harvester, this is a one of a kind Berry Harvester that was specifically designed to handle fresh pick blueberries.

Contact Information

732 W. Saint Joseph Street

Lawrence, MI 49064

Phone: 269-539-4700 Fax: 269-539-4705

sale@industrialpackagingmachines.com