Top Automatic Packing Machines to Look for in 2025 for Efficient Packaging

In an era where efficiency and speed are paramount, the automatic packing machine industry is poised for significant advancements in the coming years. As we look towards 2025, industry experts emphasize the importance of integrating innovative technologies to meet the ever-evolving demands of packaging. Dr. Sarah Thompson, a leading authority in automation solutions, aptly stated, "The future of packaging lies in the seamless integration of advanced automation to enhance productivity and reduce operational costs." This perspective underscores the necessity for businesses to evaluate the latest automatic packing machines that will reshape the landscape of packaging processes.

With growing market demands and sustainability concerns, companies must stay ahead by adopting cutting-edge automatic packing machines that streamline operations and minimize waste. These machines not only contribute to higher efficiency but also ensure consistent product quality and enhanced safety standards. As we delve into the top automatic packing machines to look for in 2025, it is essential for manufacturers and suppliers to remain informed about emerging technologies and trends that will influence their packaging strategies. The upcoming innovations promise to optimize packaging workflows and offer solutions that address both current challenges and future needs in the industry.

Top Trends in Automatic Packing Machines for 2025 Industry Insights

As the packaging industry moves towards 2025, automatic packing machines are evolving significantly to meet the increasing demands for efficiency and sustainability. One of the top trends shaping this technology is the integration of advanced robotics and artificial intelligence. These innovative machines are designed to optimize packaging processes by utilizing real-time data analytics. This not only enhances operational efficiency but also improves the accuracy of packing, allowing companies to reduce waste and maximize the utilization of resources.

Another prominent trend is the emphasis on eco-friendly materials and practices. Manufacturers are increasingly focusing on machines that can accommodate biodegradable packaging solutions. This shift towards sustainability is driven by both regulatory pressures and consumer preferences, pushing industries to adopt practices that minimize their environmental impact. Additionally, automatic packing machines are being designed for versatility, enabling them to handle a wider range of products and packaging forms, which is essential as market demands shift rapidly. Emphasizing these aspects, the future of automatic packing machines looks poised to create a more efficient and sustainable packaging landscape.

Key Features to Consider for Efficiency in Automatic Packing Machines

When considering efficient automatic packing machines for 2025, it's crucial to look at key features that enhance productivity and streamline operations. A primary aspect to evaluate is the machine's speed and throughput. Machines designed to handle various packing requirements quickly can reduce bottlenecks in the packing process, ensuring that products reach customers faster without compromising quality.

Another significant feature to consider is the machine's flexibility. Automatic packing machines that can accommodate different package sizes and types can greatly benefit businesses facing fluctuating demands. Additionally, look for machines equipped with advanced technology like artificial intelligence and machine learning capabilities. These technologies can optimize performance, reduce waste, and adapt to specific packaging needs in real-time.

Tips: When selecting an automatic packing machine, invest time in understanding the maintenance requirements. Regular upkeep can prevent downtime and prolong the machine’s lifespan. Also, consider user-friendly interfaces that simplify operations and training for staff, leading to increased efficiency on the production line. Ensure the system you choose has robust support and training options to facilitate seamless integration into your existing processes.

Market Analysis: Growth Projections for Automatic Packing Machines by 2025

The market for automatic packing machines is expected to witness significant growth by 2025, driven by advancements in technology and an increasing demand for efficient packaging solutions across various industries. According to a recent report by Smithers Pira, the global market for packaging automation is projected to exceed $20 billion, with an annual growth rate of over 5%. This surge is primarily fueled by the rise of e-commerce, which has intensified the need for reliable and faster packing processes to meet consumer expectations for quick delivery.

Moreover, innovations in artificial intelligence and robotics are set to further enhance the capabilities of automatic packing machines. Research conducted by Grand View Research highlights that the integration of such technologies can improve packaging accuracy and reduce labor costs by up to 30%. By 2025, it is anticipated that industries such as food and beverage, pharmaceuticals, and consumer goods will significantly invest in automatic packing solutions, ensuring a competitive edge through optimized operations and improved productivity. The focus on sustainability in packaging practices is also influencing this market, encouraging the development of machines that utilize eco-friendly materials and processes.

Technological Innovations Shaping the Future of Automatic Packing Tools

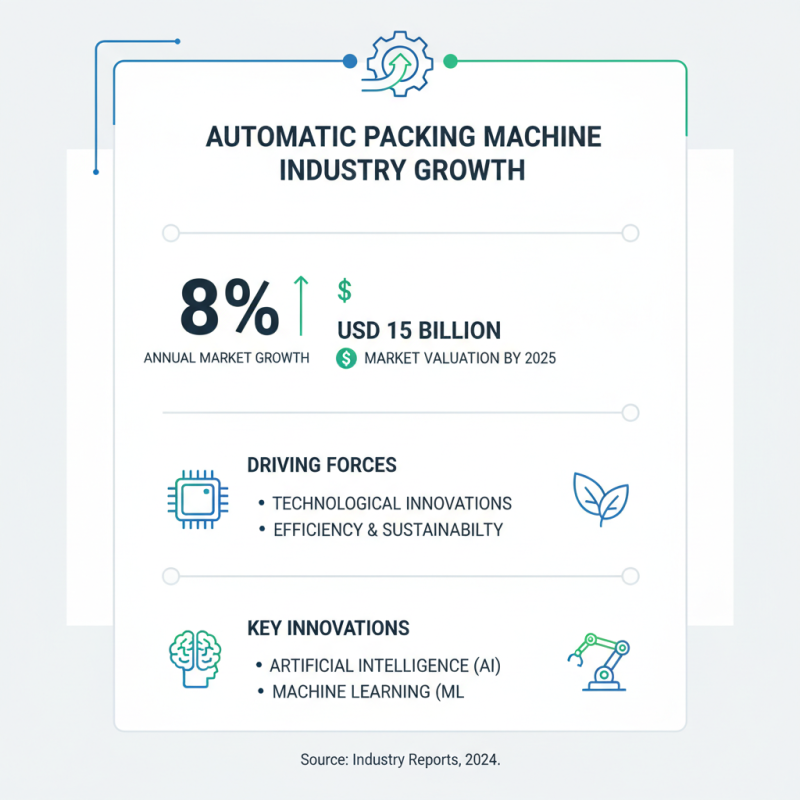

As the packaging industry evolves, the demand for automatic packing machines continues to rise, driven by technological innovations that enhance efficiency and sustainability. Reports indicate that the market for automated packing solutions is expected to grow by 8% annually, reaching a valuation of USD 15 billion by 2025. Innovations such as artificial intelligence and machine learning are transforming traditional packing processes by optimizing workflow and reducing waste.

One notable development is the integration of IoT (Internet of Things) in packing machines, enabling real-time monitoring and data analysis. This connectivity allows operators to identify inefficiencies and streamline operations, crucial for maintaining competitiveness. Additionally, advanced robotics are now capable of handling complex packaging tasks with precision, significantly reducing labor costs while improving production speed. According to a recent study, companies that adopt such technologies can improve their packaging throughput by as much as 35%.

**Tips:** When considering automatic packing solutions, prioritize machines that offer adaptability to different packaging types. This versatility can save resources and time as products evolve. Additionally, ensure that your selected packing equipment complies with sustainability practices, such as reduced energy consumption and recyclable materials usage, to meet both regulatory standards and consumer expectations in the coming years.

Sustainability Trends in Packing Machines: Eco-Friendly Solutions for 2025

As we look ahead to 2025, sustainability is set to become a defining factor in the development of automatic packing machines. The packaging industry is increasingly recognizing its responsibility to reduce environmental impact, leading to innovations aimed at minimizing waste and utilizing eco-friendly materials. Biodegradable films, recycled materials, and plant-based packaging solutions are being integrated into the production process, allowing companies to not only comply with regulations but also meet consumer demand for greener options.

Additionally, energy efficiency is an essential consideration for the packaging machines of the future. Manufacturers are focusing on creating machines that consume less power while maintaining or even enhancing their operational capabilities. Intelligent systems designed for optimized energy use can significantly reduce the carbon footprint of packaging operations. Furthermore, the incorporation of renewable energy sources, such as solar power, is gaining traction, demonstrating a commitment to sustainability throughout the production lifecycle. These trends indicate a clear shift toward not just innovative packaging solutions, but also an eco-conscious approach that will shape the landscape of the industry in the coming years.

Top Automatic Packing Machines - Sustainability Trends for 2025

Related Posts

-

How to Choose the Right Box Packing Machine for Your Business Needs

-

How to Choose the Right Automatic Packaging Machine for Your Business Needs

-

Top 10 Bagging Machines for Efficient Packaging Solutions and Cost Savings

-

2025 Top 5 Blueberry Harvesters with Industry Insights and Performance Analytics

-

How to Maximize Your Fresh Harvester Efficiency in 2025

-

2025 Guide: How to Choose the Best Bag Sealing Machine for Your Needs

A & B Packing Equipment

A&B has become the leader in fresh packing and cleaning equipment for fruits and vegetables worldwide. We have achieved this by relentlessly working to produce new and innovative ideas, along with the best customer service on Earth combined with hard working, dedicated, loyal employees and the latest industrial manufacturing techniques. We are now proud to say that we manufacture The Fulcrum Fresh Harvester, this is a one of a kind Berry Harvester that was specifically designed to handle fresh pick blueberries.

Contact Information

732 W. Saint Joseph Street

Lawrence, MI 49064

Phone: 269-539-4700 Fax: 269-539-4705

sale@industrialpackagingmachines.com