Top 10 Best Bag Filling Machines for Efficient Packaging Solutions?

In the competitive landscape of packaging, choosing the right bag filling machine is crucial. Experts like Sam Richard, a senior engineer at FillTech Solutions, emphasize its importance: "An efficient bag filling machine can drastically improve your production speed." The versatility of these machines allows businesses to adapt to various products, from powders to granules.

Selecting the best bag filling machine may seem straightforward, but it reveals complexities. Factors like speed, accuracy, and ease of use must be considered. Users often overlook maintenance requirements, which can affect long-term efficiency. A well-chosen machine can enhance productivity while a poor choice can lead to bottlenecks.

While the top 10 list aims to guide buyers, one must reflect on their specific needs. Not every feature suits every business. Balancing cost and functionality is essential, as is considering future scalability. Understanding these aspects can lead to better investment decisions in the bag filling machine sector.

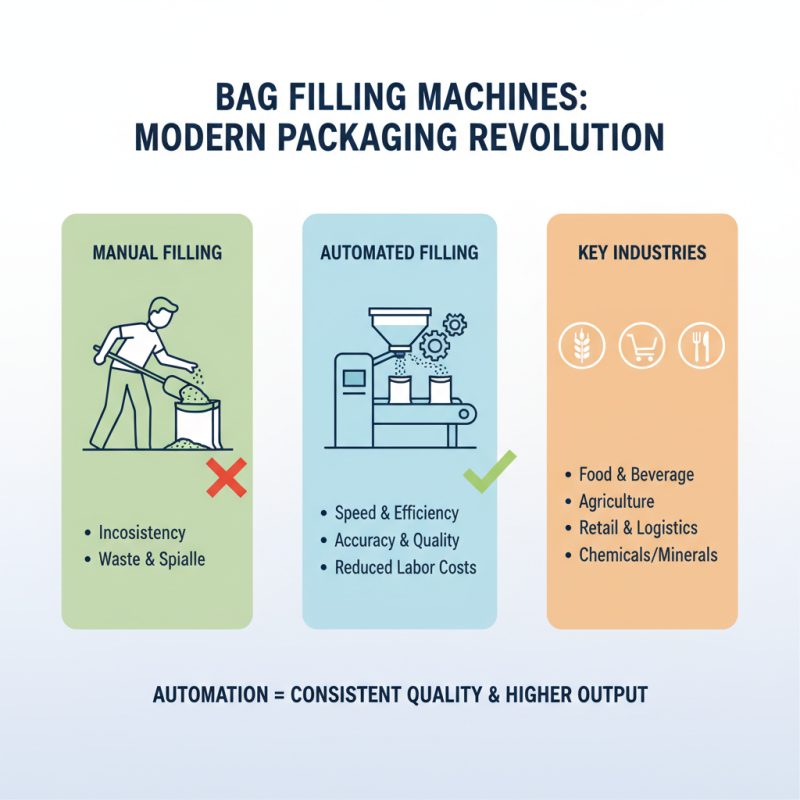

Introduction to Bag Filling Machines and Their Importance

Bag filling machines play a crucial role in modern packaging. They simplify the process of filling bags with products, increasing efficiency. This is especially important in industries like food, agriculture, and retail. Manual filling can lead to inconsistencies and waste. Automation helps maintain quality and speed.

When choosing a bag filling machine, consider your product type. Dry goods, liquids, and granular items require different equipment. Ensure the machine fits your needs. Proper maintenance is key. Neglecting upkeep can lead to malfunctions. Regular checks can extend the life of your equipment.

**Tips:** Always test the machine with your product before full-scale production. This will help identify any issues early on. Look into the ease of cleaning the machine, as hygienic standards are vital in many industries. Regular training for staff can also enhance efficiency.

Types of Bag Filling Machines Available on the Market

When it comes to packaging, choosing the right bag filling machine is essential. Various types of machines cater to different needs. For example, volumetric fillers are popular for dry products. They measure the product volume accurately. These machines are often used in the food industry. But, they might not be suitable for all product types. Liquid fillers, on the other hand, handle wet materials effectively. They ensure precise filling, which is crucial for consistent quality.

Another type is auger filling machines. They are ideal for powders and granules. The auger mechanism allows for controlled filling. However, these machines can be challenging to clean. The process requires careful handling to avoid contamination. Additionally, there are weigh filler machines. They use scales to ensure accurate filling. This type is versatile but can be more expensive. Users must weigh the cost against benefits.

Each machine type has its advantages and drawbacks. Assessing the specific application is vital. Understanding the product characteristics plays a key role in decision-making. Sometimes, it's easy to overlook the maintenance needs of these machines. Regular upkeep ensures longevity and reliability. Finding the perfect machine requires thoughtful consideration. It's a process that combines technical knowledge with practical experience.

Top 10 Best Bag Filling Machines for Efficient Packaging Solutions

This bar chart displays the filling speed in bags per hour for the top 10 bag filling machines available on the market. Efficient packaging solutions are crucial for optimizing productivity and meeting demand.

Key Features to Consider When Choosing a Bag Filling Machine

When choosing a bag filling machine, there are essential features to consider. Speed is crucial for efficiency. Many machines achieve speeds of up to 40 bags per minute, which can significantly enhance productivity. The right machine can boost your packaging line's overall output. However, balance speed with accuracy. A high-speed machine that sacrifices precision can lead to waste.

Another important factor is the machine's versatility. Many businesses deal with various bag sizes and product types. A machine that can handle multiple specifications saves time and money. According to industry reports, the ability to switch easily between different bag types can reduce downtime by as much as 30%. Ensure the chosen machine meets your specific needs.

Maintenance is a key consideration too. Regular upkeep is necessary for longevity. Some machines require more frequent servicing, which increases costs. Ensure you understand the maintenance demands of any potential machinery. Tips: Always consider the total cost of ownership, not just the initial price. Investing in user-friendly controls can also reduce training time, making operations smoother.

Top 10 Best Bag Filling Machines for Efficient Packaging Solutions

| Machine Type | Filling Capacity (bags/hour) | Bag Size Range (mm) | Weight (kg) | Power Supply (V) | Features |

|---|---|---|---|---|---|

| Vertical Form Fill Seal | 300 | 100-500 | 150 | 220 | Automated sealing, easy maintenance |

| Auger Filling Machine | 200 | 50-400 | 200 | 220 | Precision filling, adjustable settings |

| Net Weigh Filling Machine | 150 | 100-1000 | 250 | 380 | High accuracy, digital controls |

| Bulk Bag Filler | 80 | 400-1200 | 400 | 220 | Heavy-duty construction, fast cycle time |

| Pneumatic Filling Machine | 500 | 150-600 | 180 | 110 | Versatile applications, reduced contamination |

| Semi-Automatic Bagger | 150 | 200-700 | 100 | 220 | User-friendly, compact design |

| Fully Automatic Bagger | 600 | 100-1000 | 300 | 380 | Comprehensive automation, high productivity |

| Gravity Filling Machine | 250 | 100-500 | 120 | 220 | Simple operation, cost-effective |

| FIBC Filling Machine | 100 | 500-1500 | 350 | 220 | Large capacity, stable performance |

| Manual Bagging Machine | 50 | 50-300 | 60 | 110 | Cost-effective, applicable for small scales |

Top 10 Highly Rated Bag Filling Machines in 2023

In today's fast-paced manufacturing environment, efficient packaging is crucial. Bag filling machines streamline this process significantly. They help companies save time and reduce labor costs. Selecting the right machine can be challenging, especially with so many options available in 2023. It requires careful consideration of various factors. Users often get overwhelmed by features and specifications.

When evaluating bag filling machines, think about the production volume. Some machines are designed for high-capacity operations. Others are ideal for small batches. The setup can be tricky, and adjustments may be needed for different materials. A machine that works well with one type of bag may struggle with another. It's crucial to ensure compatibility to avoid downtime.

Many users appreciate machines with easy troubleshooting features. However, some models lack clear instructions, leaving operators frustrated. Maintenance is another aspect to consider. Regular upkeep is necessary for optimal performance. Users must be prepared to invest time in learning the nuances of their machines. While some machines excel in speed, they may falter in accuracy. Evaluating these trade-offs is essential for making the best choice.

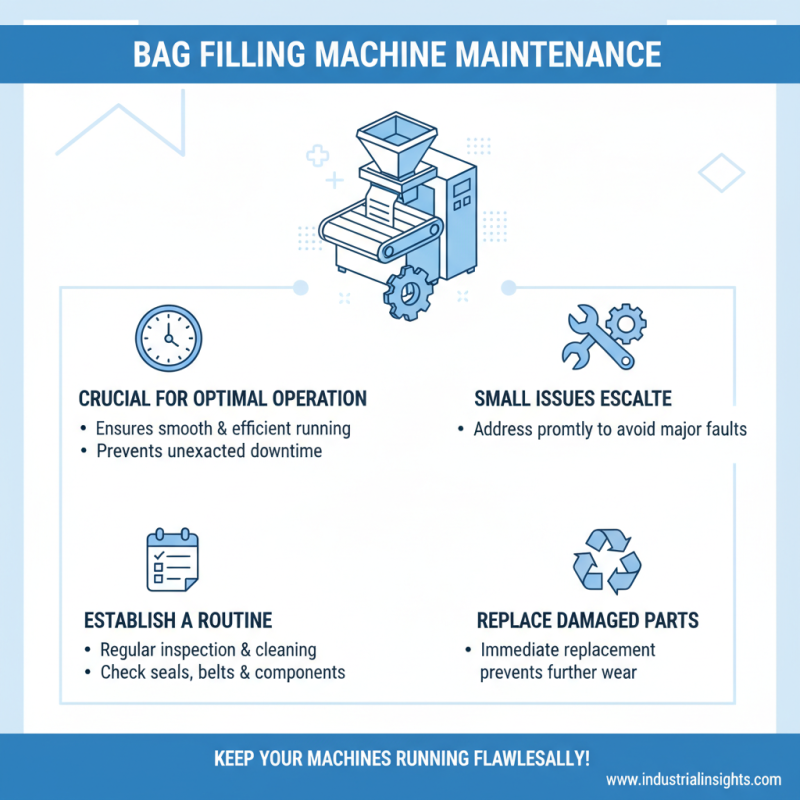

Maintenance and Best Practices for Optimal Machine Performance

Regular maintenance is crucial for bag filling machines. It ensures they operate smoothly and efficiently. Neglecting this can lead to unexpected downtime. A small issue can escalate quickly if not addressed. It's important to establish a routine for inspection and cleaning. Check for wear and tear on components like seals and belts. Replace any damaged parts immediately.

Operators should also be trained in best practices. They must know how to calibrate the machines properly. Incorrect settings can impact the filling accuracy. Regularly review operational data to identify patterns or anomalies. This analysis can highlight areas needing attention. Sometimes, operators overlook minor errors that lead to bigger inefficiencies.

In addition, ensuring a clean workspace is vital. Dust and debris can affect machine performance. Create an area around the machine that’s free from clutter. This may seem simple, but it makes a significant difference. Engage the team in maintaining the work environment. A small effort can prevent larger issues down the road.

Related Posts

-

2026 Best Automated Packaging Solutions for Efficient Production?

-

What is an Automatic Packaging Machine and How Does It Work?

-

How to Choose the Right Pouch Filling Machine for Your Business?

-

Why Choose an Automatic Packing Machine for Your Business?

-

The Ultimate Guide to Choosing the Best Package Machine in 2025

-

How to Choose the Right Box Packing Machine for Your Business Needs

A & B Packing Equipment

A&B has become the leader in fresh packing and cleaning equipment for fruits and vegetables worldwide. We have achieved this by relentlessly working to produce new and innovative ideas, along with the best customer service on Earth combined with hard working, dedicated, loyal employees and the latest industrial manufacturing techniques. We are now proud to say that we manufacture The Fulcrum Fresh Harvester, this is a one of a kind Berry Harvester that was specifically designed to handle fresh pick blueberries.

Contact Information

732 W. Saint Joseph Street

Lawrence, MI 49064

Phone: 269-539-4700 Fax: 269-539-4705

sale@industrialpackagingmachines.com