How to Choose the Best Automatic Bag Filling Machine for Your Business Needs

When it comes to streamlining packaging processes in any business, the role of an automatic bag filling machine cannot be overstated. These machines are designed to enhance efficiency, reduce labor costs, and maintain consistency in product packaging. With a plethora of options available in the market, selecting the right automatic bag filling machine tailored to your specific operational needs can be a daunting task. It requires careful consideration of various factors, from the type of product being packaged to the desired output speed.

Understanding the features and capabilities of different automatic bag filling machines is crucial for making an informed decision. Certain machines excel in handling bulk materials, while others are better suited for smaller, lightweight products. Additionally, factors such as ease of use, maintenance requirements, and compatibility with other processing equipment should be prioritized. This introductory guide will explore essential considerations that will help you navigate the selection process, ensuring that your investment leads to increased productivity and efficiency in your business operations.

Factors to Consider When Selecting an Automatic Bag Filling Machine

When selecting an automatic bag filling machine for your business, several key factors should be taken into account to ensure it meets your specific needs. First and foremost, consider the type of product you’ll be packaging. Different machines are designed to handle various materials such as powders, granules, or liquids, and understanding the nature of your product is critical in making the right choice. For example, if you're filling finely powdered items, a machine with a precise volumetric filling system would be your best bet.

Additionally, assess the production speed you require. Different machines offer varying fill rates, so it's important to align your choice with your production goals. If you're operating in a high-demand environment, a faster machine could boost your throughput significantly. Conversely, for smaller operations or specialized products, a machine that allows for greater flexibility and ease of adjustment may be more beneficial.

**Tips:** Always evaluate the machine's compatibility with your existing packaging line to guarantee a seamless integration. Additionally, check the machine's maintenance requirements to ensure that it won’t become a bottleneck in your production process. Finally, consider the available support and service options from manufacturers, as a reliable support system can be invaluable to your operations.

How to Choose the Best Automatic Bag Filling Machine for Your Business Needs

| Feature | Importance | Considerations |

|---|---|---|

| Filling Speed | High | Evaluate required speed based on production volume. |

| Bag Size Compatibility | Medium | Ensure the machine supports various bag sizes. |

| Machine Construction | High | Look for durable materials that fit production environment. |

| Automation Level | High | Choose a machine that minimizes manual intervention. |

| Flexibility | Medium | Assess the ability to handle various materials and products. |

| Maintenance Requirements | Medium | Consider ease of maintenance and downtime. |

| Cost | High | Balance features against budget constraints. |

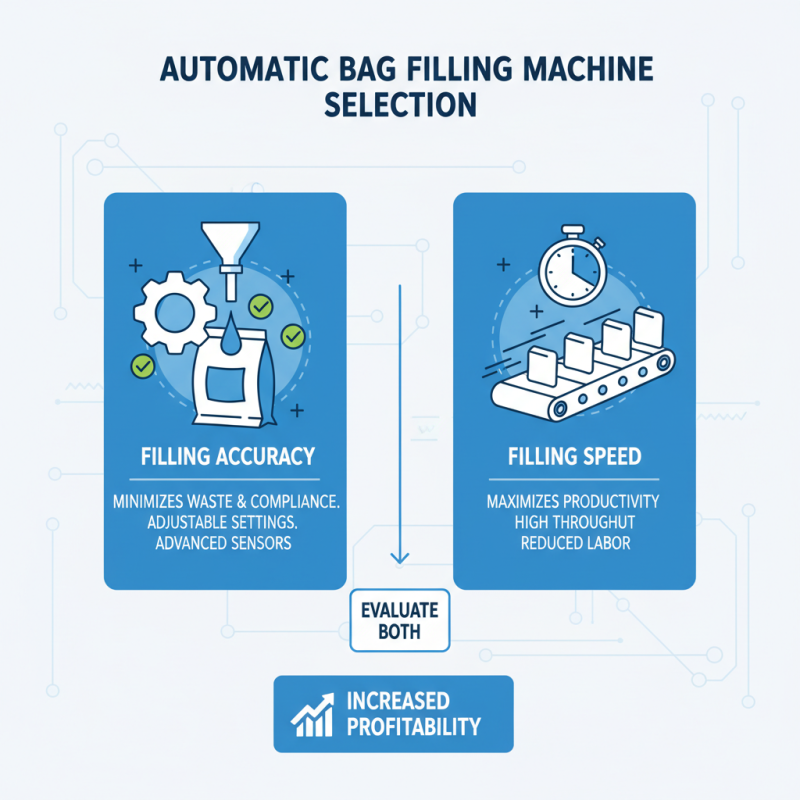

Evaluating Filling Accuracy and Speed for Optimal Productivity

When selecting an automatic bag filling machine, evaluating filling accuracy and speed is crucial for maximizing productivity. A machine that delivers high filling accuracy ensures that each bag contains the right amount of product, minimizing waste and adhering to regulatory standards. This accuracy can be influenced by several factors, including the design of the filling mechanism and the calibration process. Businesses should prioritize machines with adjustable settings that can accommodate different product types and weights, as well as those equipped with advanced sensors for real-time monitoring.

Speed is another vital consideration in the selection process. An efficient filling machine should not only fill bags quickly but also maintain accuracy under higher throughput conditions. It's essential to assess the machine's cycle time and how it integrates with the overall production line to avoid bottlenecks. Solutions that offer customizable speed settings, as well as features that allow for quick changeovers between bag sizes, can greatly enhance operational efficiency. By carefully evaluating both filling accuracy and speed, businesses can ensure that they select a filling machine that meets their specific operational demands while boosting overall productivity.

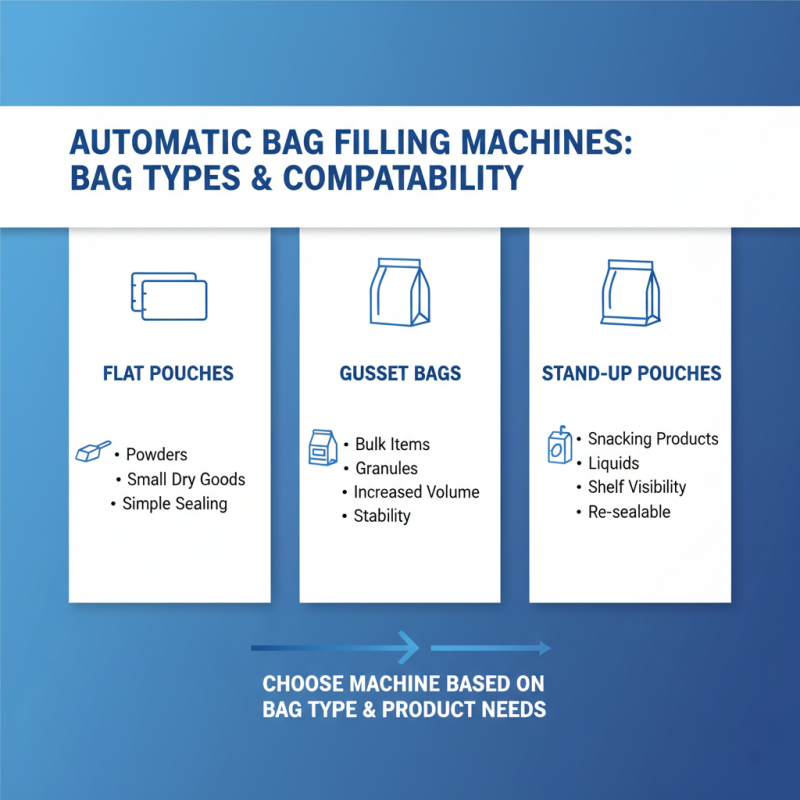

Assessing Different Bag Types and Their Compatibility with Machines

When selecting an automatic bag filling machine, understanding the various types of bags available and their compatibility with different machines is crucial. The most common bag types include flat pouches, gusset bags, and stand-up pouches, each designed for specific applications and products. Flat pouches are ideal for dry goods like powders and powders, while gusset bags offer more volume and stability for bulkier items. Stand-up pouches, on the other hand, are excellent for products that require shelf stability and visibility. Assessing the primary use cases of these bags will guide you in choosing a machine that can effectively handle your preferred packaging solutions.

Compatibility between bags and filling machines extends to factors such as material thickness, sealing methods, and footprint of the bags. Machines must be able to seal the chosen bags properly, whether that requires heat sealing, pressure sealing, or filling via a spout. Furthermore, consider the filling speed and capacity of the machine to ensure it aligns with your production output requirements. A thoughtfully chosen automatic bag filling machine not only enhances efficiency but also helps maintain the quality and integrity of your products, making it essential to assess each bag type's characteristics and their relationship with the machinery effectively.

Cost Analysis: Balancing Initial Investment and Long-Term Savings

When investing in an automatic bag filling machine, a thorough cost analysis is essential to balance the initial investment with potential long-term savings. The upfront costs can vary significantly depending on the machine's specifications and capabilities. However, understanding the operational costs and efficiency gains that a machine can bring often justifies the initial expenditure. For instance, machines that offer faster filling speeds and greater accuracy can lead to considerable savings in labor and reduced product waste over time.

Tips for evaluating total cost of ownership include considering maintenance expenses, energy consumption, and the availability of spare parts. A machine with higher upfront costs might actually save money in the long run if it requires fewer repairs and has lower running costs. Additionally, assessing the warranty and support services offered by the manufacturer can provide added assurance and minimize future expenses related to downtime.

Another factor is scalability. Choosing a machine that can adapt to your business's growth can save costs in the future, as you won't need to replace equipment or invest in new machines as your production demands increase. Investing time to analyze these aspects ensures that your choice aligns with your business needs and financial strategy, leading to greater profitability in the years to come.

Examining Maintenance Requirements for Longevity and Performance

When choosing an automatic bag filling machine, understanding its maintenance requirements is crucial for ensuring both longevity and optimal performance. Regular maintenance helps to prevent unexpected breakdowns, which can lead to costly downtime and decreased productivity. Basic tasks include routine inspections, cleaning, and lubrication of moving parts. Establishing a maintenance schedule aligned with the machine’s operational demands can make a significant difference in its lifespan.

Additionally, it's important to familiarize yourself with the specific maintenance needs outlined in the manufacturer’s manual. Some machines may require more frequent checks based on the type of materials being handled or the production volume. Key components, such as sensors and conveyor belts, should be monitored closely for wear and tear. Investing in quality maintenance not only extends the machine's life but also enhances its efficiency, ensuring that your production goals are consistently met without interruption.

Performance and Maintenance Requirements of Automatic Bag Filling Machines

Related Posts

-

2025 How to Choose the Best Automatic Bag Filling Machine for Your Business

-

Top 10 Bagging Machines for Efficient Packaging Solutions and Cost Savings

-

How to Maximize Your Fresh Harvester Efficiency in 2025

-

How to Choose the Right Filling Machine for Your Packaging Needs

-

Top 7 Benefits of Using Fresh Harvester for Maximizing Fresh Produce Yields

-

What is the Best Packaging Machine for Small Business Startups

A & B Packing Equipment

A&B has become the leader in fresh packing and cleaning equipment for fruits and vegetables worldwide. We have achieved this by relentlessly working to produce new and innovative ideas, along with the best customer service on Earth combined with hard working, dedicated, loyal employees and the latest industrial manufacturing techniques. We are now proud to say that we manufacture The Fulcrum Fresh Harvester, this is a one of a kind Berry Harvester that was specifically designed to handle fresh pick blueberries.

Contact Information

732 W. Saint Joseph Street

Lawrence, MI 49064

Phone: 269-539-4700 Fax: 269-539-4705

sale@industrialpackagingmachines.com