Why Choose a Bag Packing Machine for Your Packaging Needs?

In today's fast-paced manufacturing environment, the efficiency and reliability of packaging processes play a crucial role in a company's overall productivity and success. As businesses strive to optimize their operations, the adoption of advanced technologies becomes increasingly vital. One such technology that has gained prominence is the bag packing machine. According to Jake Thompson, a leading expert in packaging machinery, "The implementation of a bag packing machine can drastically reduce labor costs while increasing packaging speed and consistency."

Bag packing machines are designed to automate the packaging process, which not only enhances efficiency but also ensures a higher quality of packaging. By transitioning from manual to automated solutions, companies can meet growing consumer demands without sacrificing performance. This shift allows for greater flexibility in packaging various products, which is essential in an ever-evolving market landscape.

Furthermore, using a bag packing machine offers substantial advantages in terms of reducing waste and improving sustainability efforts. With precise measurement and minimal error margins, businesses can effectively manage their resources, contributing to both economic and environmental goals. As industries continue to evolve, the bag packing machine stands out as a strategic investment for companies aiming to stay competitive and meet the diverse needs of their customers.

Benefits of Using a Bag Packing Machine in the Packaging Process

The use of a bag packing machine in the packaging process offers numerous advantages that can significantly enhance operational efficiency and product presentation. First and foremost, these machines streamline the packaging workflow, allowing for faster packing speeds compared to manual methods. This increase in speed can dramatically reduce labor costs and minimize the time products spend in the packaging stage, ultimately leading to quicker time-to-market and improved customer satisfaction.

Additionally, bag packing machines are designed to ensure precise and consistent packaging, which is crucial in maintaining product integrity. They minimize the risk of human error, which can lead to inconsistencies in bag weights or sizes. This precision not only enhances the overall quality of the packaging but also helps in meeting regulatory requirements for product labeling and safety. Furthermore, many of these machines are adjustable and versatile, capable of handling various bag sizes and materials, making them a valuable asset for businesses looking to diversify their product offerings without significant additional investment in packaging technology.

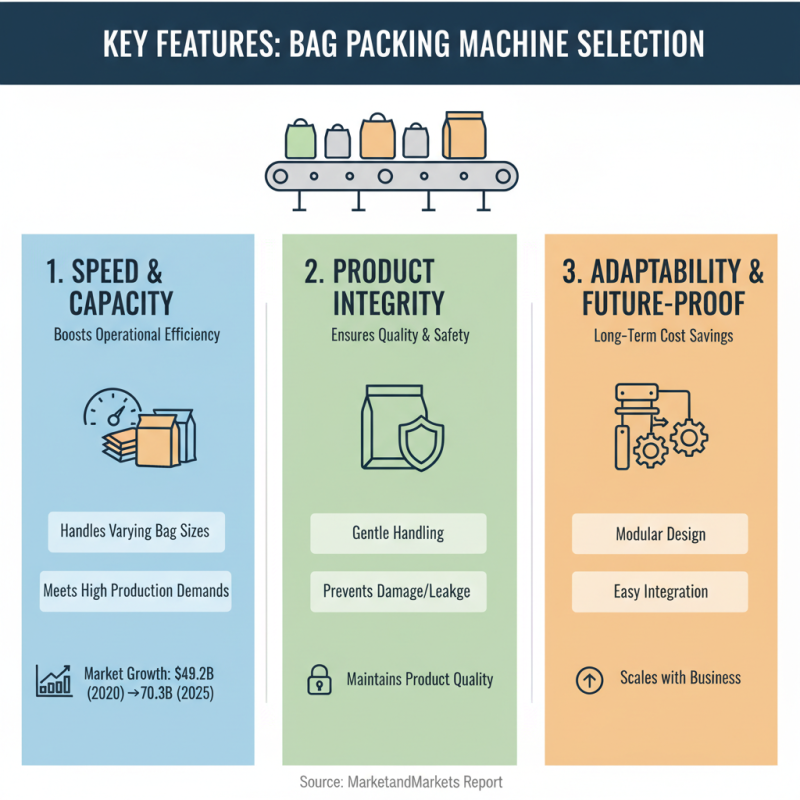

Key Features to Consider When Selecting a Bag Packing Machine

When selecting a bag packing machine for your packaging needs, there are several key features to consider that can significantly impact your operational efficiency and product integrity. Firstly, the machine's speed and capacity are paramount; according to a report by MarketsandMarkets, the global packaging machinery market is expected to grow from $49.2 billion in 2020 to $70.3 billion by 2025, highlighting the increasing demand for high-performance solutions. A machine that can handle varying bag sizes while maintaining speed ensures that you can meet production demands without sacrificing quality.

Another essential consideration is ease of use and maintenance. A user-friendly interface can minimize training time for operators, while regular maintenance checks can prolong the lifespan of the machine. According to a study published by PMMI (Packaging Machinery Manufacturers Institute), organizations that invest in well-designed equipment with easy maintenance reported a 20% decrease in downtime compared to those using older machinery.

Tips: Before making a purchase, assess the available adjustment features for different bag types and sizes. Additionally, consider machines with automated cleaning systems, as these can save time and reduce labor costs. Always verify the machine’s compatibility with your current production line to optimize workflow and efficiency.

Comparing Bag Packing Machines to Traditional Packaging Methods

When evaluating packaging options, it’s essential to weigh the benefits of bag packing machines against traditional methods. Traditional packaging often relies on manual labor, which can lead to inconsistencies in packaging quality, increased labor costs, and slower production rates. These methods, while familiar, can struggle to meet the demands of high-volume production and modern supply chain requirements. Manual packaging processes may result in operator fatigue and errors, contributing to product waste and inefficiencies.

In contrast, bag packing machines streamline the packaging process through automation, allowing for higher precision and consistency. These machines are capable of handling various bag sizes and materials, making them versatile for different products. Automated systems not only speed up the packing process but also minimize the risk of contamination and damage during packaging. Moreover, the integration of advanced technologies in bag packing machines enables better tracking and management of inventory, ensuring that businesses can adapt quickly to market changes. Ultimately, the shift to bag packing machines signifies a move towards enhanced efficiency and reliability in packaging operations.

Applications of Bag Packing Machines Across Different Industries

Bag packing machines have become indispensable tools in various industries, facilitating efficient and consistent packaging solutions. These machines find applications in sectors such as food and beverage, pharmaceuticals, agriculture, and manufacturing. According to a report by Research and Markets, the global bagging machine market is projected to reach $4.1 billion by 2027, growing at a CAGR of 4.5%. This significant growth indicates the increasing demand for automated packaging solutions that enhance productivity and reduce labor costs.

In the food and beverage industry, bag packing machines are crucial for packaging products ranging from granules to liquids. Specifically, the machine's ability to ensure a hermetic seal prevents contamination and prolongs shelf life, essential for maintaining quality. The pharmaceutical sector also benefits from these machines, where precise dosing and sterile packaging are vital. A study from the International Journal of Pharmaceutical Sciences highlights that around 60% of pharmaceutical companies are increasingly adopting automated packaging systems to comply with stringent regulatory standards.

Tips for selecting the right bag packing machine include assessing product characteristics, such as size and material, and understanding the production volume to determine the machine's capacity. Additionally, consider the flexibility of the machine to handle various bag types and formats, which can enhance adaptability in a rapidly changing market. Understanding maintenance requirements and available support can also contribute to optimizing machine performance and longevity.

Cost-Effectiveness and Efficiency of Automated Bag Packing Solutions

Automated bag packing machines offer significant cost-effectiveness and efficiency, making them an ideal solution for various packaging needs. By streamlining the packing process, these machines drastically reduce the labor costs associated with manual packing. Businesses can save on wages and reduce the risk of labor-related issues, such as training and turnover. Moreover, the initial investment in automated equipment is often offset by the savings generated over time, as machines can operate at higher speeds and with fewer errors than manual methods.

Efficiency is another critical aspect of using bag packing machines. These machines are designed to optimize the packing process, allowing for consistent and reliable packaging results. With advanced technology, automated systems can easily adjust to different bag sizes and materials, ensuring flexibility for various products. The fast and accurate packing reduces cycle times, enabling companies to increase their throughput without sacrificing quality. Overall, the combination of reduced labor costs and enhanced efficiency makes automated bag packing solutions a smart choice for businesses looking to improve their packaging operations.

Cost-Effectiveness and Efficiency of Automated Bag Packing Machines

Related Posts

-

How to Choose the Right Box Packing Machine for Your Business Needs

-

How to Choose the Right Box Packing Machine for Your Business Needs

-

How to Use a Process Harvester for Efficient Resource Management

-

2025 Top 10 Bagging Machines: Revolutionizing Packaging for Efficiency

-

2025 How to Choose the Best Automatic Bag Filling Machine for Your Business

-

What is the Best Packaging Machine for Small Business Startups

A & B Packing Equipment

A&B has become the leader in fresh packing and cleaning equipment for fruits and vegetables worldwide. We have achieved this by relentlessly working to produce new and innovative ideas, along with the best customer service on Earth combined with hard working, dedicated, loyal employees and the latest industrial manufacturing techniques. We are now proud to say that we manufacture The Fulcrum Fresh Harvester, this is a one of a kind Berry Harvester that was specifically designed to handle fresh pick blueberries.

Contact Information

732 W. Saint Joseph Street

Lawrence, MI 49064

Phone: 269-539-4700 Fax: 269-539-4705

sale@industrialpackagingmachines.com