How to Choose the Best Packing Equipment for Your Business Needs

In today's fast-paced business environment, selecting the appropriate packing equipment is crucial for enhancing operational efficiency and ensuring product safety. According to a recent report by MarketsandMarkets, the global packing equipment market is projected to reach $47.5 billion by 2025, growing at a CAGR of 5.2% from 2020. This growth underscores the increasing importance of effective packing solutions in various industries, from food and beverage to pharmaceuticals, where timely and damage-free delivery is paramount.

Renowned packing equipment expert Dr. Emily Foster emphasizes the significance of tailored solutions, stating, "Choosing the right packing equipment not only minimizes product waste but also plays an integral role in streamlining logistics operations." With this perspective in mind, businesses must consider their unique requirements, such as product type, volume, and distribution channels when evaluating packing equipment options. This strategic approach allows companies to optimize costs while maintaining quality, thereby fostering customer satisfaction in an increasingly competitive marketplace.

Identifying Your Business's Specific Packing Requirements

When selecting packing equipment, understanding your business's specific packing requirements is crucial. Each business operates under unique circumstances influenced by the nature of its products, target market, and distribution methods. For instance, companies in the food industry may need packing solutions that comply with health and safety standards, while e-commerce businesses might prioritize equipment that ensures protection during transportation. Evaluating these specific needs allows you to narrow down your options effectively.

Moreover, considering factors such as the volume of items that need packing, the size and weight of products, and any special packaging needs further refines your search. High-speed packing machinery may be necessary for businesses with large output demands, while smaller operations could benefit from manual packing stations that offer flexibility. Additionally, businesses should assess their budget, space constraints, and the potential for automation in their packing processes. By clearly identifying these requirements, businesses can select packing equipment that optimally aligns with their operational goals and enhances overall efficiency.

Evaluating Different Types of Packing Equipment Available

When selecting packing equipment for your business, it's essential to evaluate the various options available in the market to ensure that you meet your specific operational needs. The packing equipment sector is diverse, with products ranging from manual tools, such as hand sealers and tape dispensers, to fully automated packing machines that can significantly enhance efficiency and output. According to a report by Fortune Business Insights, the global packaging machinery market is expected to reach USD 63.8 billion by 2028, indicating a robust growth driven by advancements in automation and efficiency.

One of the primary considerations when choosing packing equipment is the type of materials you will be working with. For instance, if your operation involves fragile goods, equipment that offers superior cushioning and protection characteristics, such as bubble wrap dispensers or foam-in-place systems, would be ideal. On the other hand, high-speed packing lines may require equipment like automated case packers or palletizers that can handle various box sizes and weights, ensuring rapid throughput. Industry research suggests that companies utilizing automated packing solutions can improve productivity by up to 30%, highlighting the importance of aligning your equipment selection with your product handling requirements.

Moreover, sustainability is increasingly a factor in packing equipment decisions. As businesses seek to reduce their environmental footprint, options that facilitate recyclable or biodegradable materials are becoming more prevalent. A survey by the Packaging Association found that over 70% of companies are prioritizing eco-friendly packing solutions, demonstrating a shift towards more responsible packing practices. By carefully evaluating the available equipment types and their capabilities, businesses can make informed choices that not only meet their operational demands but also align with industry trends toward sustainability.

Assessing Cost vs. Efficiency of Packing Solutions

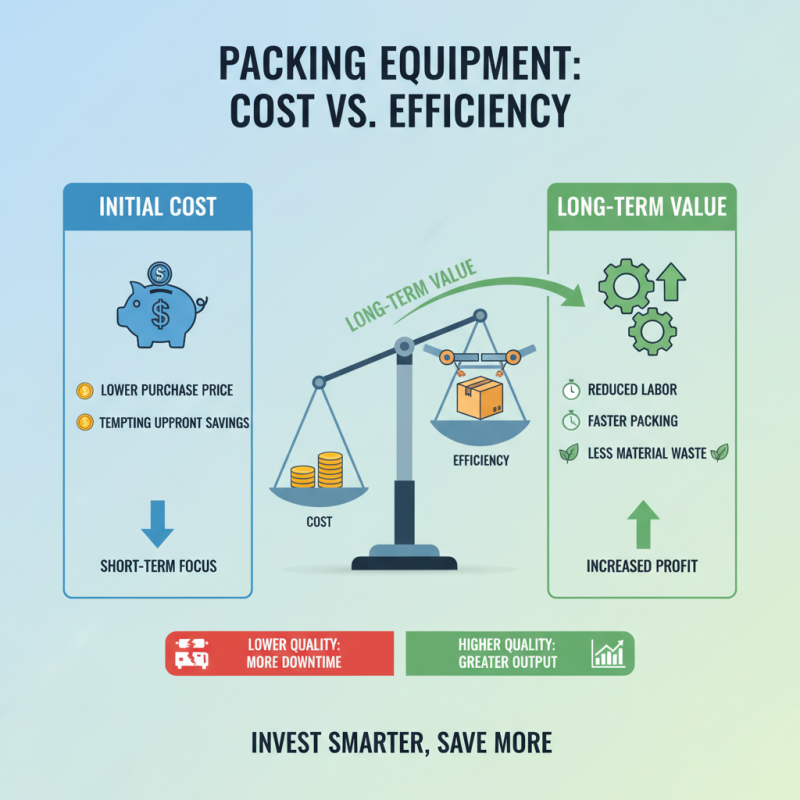

When choosing packing equipment for your business, understanding the balance between cost and efficiency is crucial. The initial purchase price of packing solutions can be tempting to prioritize, but examining the long-term operational costs is equally important. Efficient packing equipment often leads to reduced labor costs, faster packing times, and decreased material waste. By investing in higher-quality machines, businesses can achieve greater output and minimize downtime, ultimately resulting in more significant savings over time.

Furthermore, it is vital to consider the type of products being packed and the specific requirements of your packaging process. Efficient packing equipment should not only meet the immediate budget constraints but also align with the needed speed and flexibility for production. For example, a solution that is economical upfront but slow or unreliable could lead to bottlenecks, increasing overall operational costs. Therefore, conducting a thorough analysis of both the upfront and long-term costs associated with different packing solutions will pave the way for making an informed decision that suits your business needs.

Understanding the Scalability of Packing Equipment Options

When selecting packing equipment for your business, understanding scalability is crucial for long-term success. According to a report by Smithers Pira, the global packaging market is projected to reach $1 trillion by 2024, indicating a rapid growth that businesses must prepare for. Scalable packing solutions, which can adapt to changes in production volume and product types, allow companies to meet fluctuating demands without incurring significant overhead costs. For instance, modular packing machines that can be easily upgraded or expanded as production increases can significantly reduce the need for comprehensive overhauls of existing systems.

Moreover, the ability to scale effectively is closely tied to the transition towards automation in packaging operations. A study by the International Society for Automation revealed that nearly 70% of manufacturers are planning to invest in automated packing solutions to streamline operations and improve efficiency. Packaging equipment that supports automation not only enhances throughput but also offers the flexibility to implement integrated systems that cater to diverse product lines. This adaptability ultimately allows businesses to optimize their packing processes in line with evolving market trends and consumer behaviors, ensuring they remain competitive.

How to Choose the Best Packing Equipment for Your Business Needs - Understanding the Scalability of Packing Equipment Options

| Packing Equipment Type | Scalability | Cost Range | Best For | Speed |

|---|---|---|---|---|

| Semi-Automatic Packing Machines | Moderate Scalability | $5,000 - $15,000 | Small to Medium Businesses | 20-40 packages/min |

| Fully Automatic Packing Machines | High Scalability | $20,000 - $100,000 | Large Enterprises | 50-200 packages/min |

| Manual Packing Tools | Limited Scalability | $100 - $1,500 | Startups and Small Operations | 5-15 packages/min |

| Tray Sealers | Variable Scalability | $10,000 - $30,000 | Food Industry | 30-50 packages/min |

| Shrink Wrap Machines | Good Scalability | $3,000 - $25,000 | E-commerce and Retail | 15-70 packages/min |

Considering Maintenance and Support for Packing Equipment Choices

When selecting packing equipment, maintenance and support are crucial factors that can significantly impact the longevity and efficiency of your machinery. Regular maintenance ensures that your equipment operates at peak performance, reducing downtime and costly repairs. It’s advisable to choose equipment that comes with clear maintenance guidelines and readily available spare parts. Furthermore, consider equipment that provides easy access to service components, allowing your team to conduct routine checks and preventative maintenance without hassle.

Tips for maintenance: Establish a scheduled maintenance plan that includes regular inspections and part replacements. Train your staff on basic troubleshooting and maintenance procedures to prevent minor issues from escalating into major problems. Keep a maintenance log to track servicing dates and performed repairs, which can be invaluable for analyzing performance over time.

In addition to maintenance, assess the level of support offered by the equipment manufacturer or supplier. Quick access to customer support can make a significant difference in resolving issues. Look for suppliers that provide comprehensive training for your team and offer responsive customer service. Evaluate warranty options and post-purchase assistance to ensure you have the necessary support throughout the equipment’s lifecycle.

Tips for support: Research customer reviews regarding the responsiveness of the supplier’s support team. Don’t hesitate to ask potential suppliers about their support offerings during the decision-making process. Establish a reliable communication channel with your supplier, as prompt support can minimize delays in production processes.

Related Posts

-

How to Choose the Right Automatic Packaging Machine for Your Business Needs

-

How to Choose the Right Box Packing Machine for Your Business Needs

-

Top Automatic Packing Machines to Look for in 2025 for Efficient Packaging

-

How to Choose the Right Box Packing Machine for Your Business Needs

-

Understanding Process Harvester Techniques for Effective Data Management

-

How to Use a Process Harvester for Efficient Resource Management

A & B Packing Equipment

A&B has become the leader in fresh packing and cleaning equipment for fruits and vegetables worldwide. We have achieved this by relentlessly working to produce new and innovative ideas, along with the best customer service on Earth combined with hard working, dedicated, loyal employees and the latest industrial manufacturing techniques. We are now proud to say that we manufacture The Fulcrum Fresh Harvester, this is a one of a kind Berry Harvester that was specifically designed to handle fresh pick blueberries.

Contact Information

732 W. Saint Joseph Street

Lawrence, MI 49064

Phone: 269-539-4700 Fax: 269-539-4705

sale@industrialpackagingmachines.com