How to Choose the Right Box Packing Machine for Your Business Needs

In the dynamic world of packaging, selecting the ideal box packing machine is a critical decision that can significantly influence operational efficiency and product integrity. According to the latest industry report from the Packaging Machinery Manufacturers Institute (PMMI), the global market for packaging machinery is projected to reach $50 billion by 2025, highlighting the increasing reliance on automated solutions in various sectors. As companies strive to meet consumer demands for faster and more reliable packaging processes, understanding the specifications and capabilities of box packing machines becomes paramount.

Industry expert Dr. Sarah Thompson, a leading authority in packaging technology, emphasizes the importance of this decision, stating, “Choosing the right box packing machine is not just a financial investment; it’s a strategic move that can enhance productivity and reduce waste in the long run.” Given the myriad of options available, ranging from semi-automated to fully automated systems, businesses must carefully assess their specific needs, including product dimensions, speed requirements, and scalability. This ensures that the chosen box packing machine aligns with production goals and contributes to overall supply chain efficiency.

Understanding Your Business Packaging Requirements

When selecting the right box packing machine for your business, understanding your packaging requirements is paramount. Different industries have unique needs based on the type of products, production volume, and distribution methods. According to a report by Research and Markets, the global packaging machinery market is projected to grow by 4.7% annually, reaching over $50 billion by 2025. This growth underscores the increasing demand for efficient and tailored packaging solutions that can adapt to various business requirements.

It’s essential to assess your specific packaging criteria, such as box sizes, material compatibility, and production speed. If your business deals with fragile items, for example, a machine that offers adjustable cushioning features would be crucial. Additionally, consider the scalability of the machine; as the 2021 Packaging Machinery Market Analysis indicated, businesses require flexible systems that can handle changes in demand without significant downtime. Evaluating factors like automation, ease of operation, and maintenance can further enhance your efficiency and reduce operational costs over time. Understanding these aspects will ensure that you select a packing machine that aligns with your long-term business goals.

Packaging Machine Types and Their Popularity

Types of Box Packing Machines Available in the Market

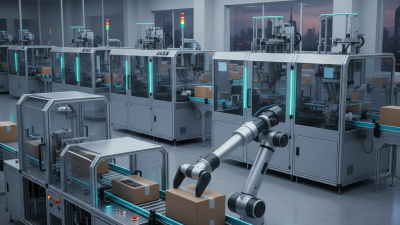

When selecting a box packing machine, it is essential to explore the various types available in the market, as each type caters to different operational needs. One of the most common types is the automatic box packing machine, which excels in high-volume production environments. According to a report by Research and Markets, the global automatic packaging machinery market was valued at approximately $40 billion in 2021 and is projected to grow significantly due to increasing demand for efficient packaging solutions.

These machines typically feature programmable controls and can handle a wide range of box sizes and types, making them ideal for businesses aiming to optimize workflow and reduce labor costs.

Another option to consider is the semi-automatic box packing machine, which offers a balance between manual and automatic processes. These machines are particularly beneficial for small to medium-sized enterprises that require flexibility without a complete reliance on automation. A market analysis from Smithers indicates that the semi-automatic segment is gaining traction due to its affordability and versatility, allowing businesses to scale operations gradually.

Additionally, specialized machines, such as those designed for fragile or oversized items, are available and should be evaluated based on specific product handling requirements. Understanding these types can significantly enhance productivity and align packaging processes with business goals.

Key Features to Consider When Selecting a Packing Machine

When selecting a box packing machine for your business, understanding the key features that cater to your specific needs is crucial. One essential aspect to consider is the machine's speed and efficiency. According to a report by Smithers Pira, the global packaging machinery market is projected to grow at a CAGR of 4.6% through 2024, driven by the demand for faster production lines and efficiency. A machine that aligns with your production speed requirements can significantly enhance throughput and meet customer demands more effectively.

Another critical feature is the versatility of packaging options. Look for machines that can easily handle various box sizes and styles. This flexibility allows businesses to adapt to changing product lines without the need for extensive modifications or new equipment. Data from the International Packaging Association indicates that companies that invest in multi-format solutions can save up to 30% on operational costs over time.

Tips: Before committing to a machine, conduct a thorough assessment of your product types and packaging requirements. Engaging with suppliers for demonstrations can provide insight into how well the machine integrates with your existing processes. Additionally, consider the ease of maintenance and support options provided by the manufacturers, as these factors can greatly influence long-term performance and reliability.

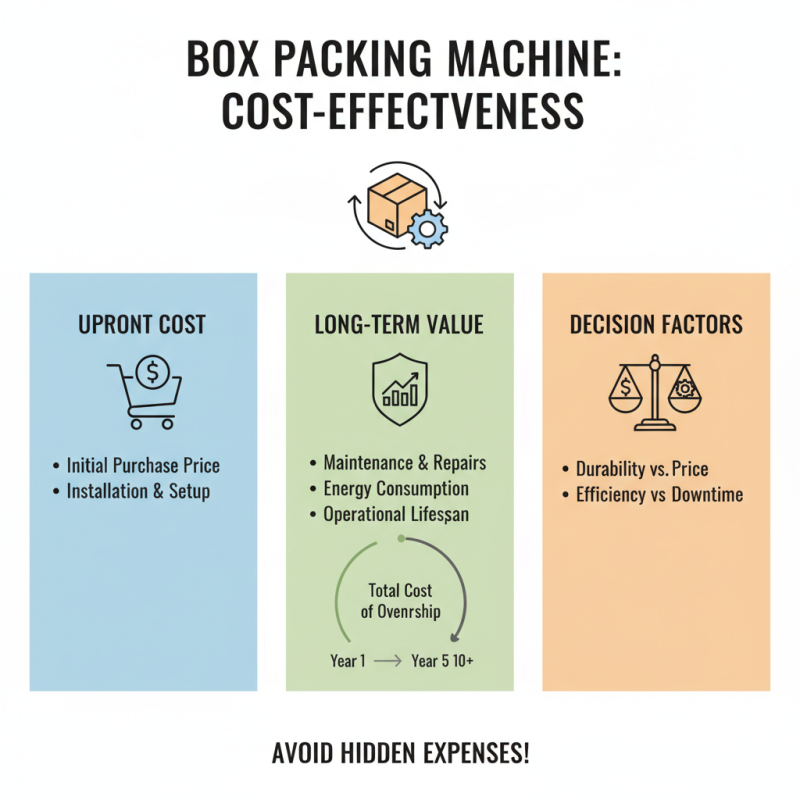

Evaluating Your Budget and Cost-Effectiveness

When selecting a box packing machine for your business, evaluating your budget and cost-effectiveness is crucial. Understand the total cost of ownership, including the initial purchase price, maintenance expenses, and the expected lifespan of the machine. A cheaper machine might save you money upfront but could lead to higher costs down the line due to frequent repairs or inefficiency. Make sure to consider all these factors to avoid unforeseen expenses that can impact your bottom line.

Tips: To maximize cost-effectiveness, consider machines that offer flexibility. Look for equipment that can handle a variety of box sizes and styles, which can save you from needing multiple machines for different tasks. Additionally, consider the machine's speed and how it aligns with your production goals. A machine that operates at higher speeds may have a steeper upfront cost but could significantly improve productivity and reduce labor costs over time.

Moreover, factor in the training and operation expenses associated with the box packing machine. If your staff requires extensive training to operate the machine efficiently, this can increase overall costs. Look for machines that are user-friendly and come with readily available training resources. Investing in a machine that is intuitive will pay off in terms of time savings and reduced error rates in packing processes.

Maintenance and Support for Long-Term Machine Performance

When acquiring a box packing machine, having a robust maintenance and support plan is essential for ensuring the long-term performance of your equipment. Regular maintenance checks can prevent unexpected breakdowns and extend the lifespan of your machine. Establishing a routine schedule that includes cleaning, lubrication, and inspection of critical components will help keep your machine running smoothly.

Tips for effective maintenance include keeping a detailed log of maintenance activities, training your staff on safe operating procedures, and being proactive about replacing worn parts before they lead to machine failure. Additionally, having access to technical support from the manufacturer can provide valuable guidance on troubleshooting and repairs, ensuring minimal disruption to your production process.

Investing in an extended warranty or service agreement may also be beneficial, as it often includes periodic maintenance visits and priority support. By prioritizing maintenance and support for your box packing machine, you not only enhance operational efficiency but also protect your investment for the future.

Related Posts

-

How to Choose the Right Box Packing Machine for Your Business Needs

-

How to Choose the Right Automatic Packaging Machine for Your Business Needs

-

What is a Vegetable Packaging Machine and How Does it Benefit Your Business

-

How to Maximize Your Fresh Harvester Efficiency in 2025

-

How to Choose the Right Filling Machine for Your Packaging Needs

-

Top 10 Benefits of Using an Automated Packaging Machine for Your Business

A & B Packing Equipment

A&B has become the leader in fresh packing and cleaning equipment for fruits and vegetables worldwide. We have achieved this by relentlessly working to produce new and innovative ideas, along with the best customer service on Earth combined with hard working, dedicated, loyal employees and the latest industrial manufacturing techniques. We are now proud to say that we manufacture The Fulcrum Fresh Harvester, this is a one of a kind Berry Harvester that was specifically designed to handle fresh pick blueberries.

Contact Information

732 W. Saint Joseph Street

Lawrence, MI 49064

Phone: 269-539-4700 Fax: 269-539-4705

sale@industrialpackagingmachines.com