How to Choose the Right Filling Machine for Your Packaging Needs

Choosing the right filling machine for your packaging needs can significantly impact your production efficiency and product quality. As industry expert John Smith, a leading consultant in packaging technology, once noted, "Selecting the appropriate filling machine is crucial for ensuring consistency and meeting consumer expectations." With a multitude of options available, understanding the specific requirements of your product and production line is essential for making an informed decision.

Filling machines come in various types and configurations, each designed to accommodate different container shapes, sizes, and product viscosities. Whether you're working with liquids, powders, or granules, the right machine can streamline your operations and enhance productivity. As such, it is vital to evaluate factors such as throughput, precision, and maintenance requirements when selecting a filling machine.

In this guide, we will explore key considerations that will help you navigate the complexities of choosing the optimal filling machine for your packaging needs. From understanding your production volume to assessing your product characteristics, a thoughtful approach will lead you to a solution that not only meets your operational goals but also aligns with your overall branding strategy.

Understanding Different Types of Filling Machines Available in the Market

When selecting the appropriate filling machine for your packaging needs, it’s essential to understand the different types available in the market. Filling machines can generally be categorized into several types, each designed for specific applications. For instance, gravity filling machines are commonly used for liquids with low viscosity, such as water or wine, whereas piston filling machines are ideal for thicker substances, including sauces or pastes. According to the Packaging Machinery Manufacturers Institute (PMMI), the demand for filling machines has been increasing at an annual rate of 4.2%, reflecting the need for more efficient and versatile machinery in various industries.

Another category includes vacuum filling machines, which are perfect for sensitive products that require minimal exposure to air, thus preserving quality. The market for these machines is showing growth as more companies focus on sustainability and product lifespan. A study by Freedonia Group noted that the market for packaging machinery is expected to reach $45 billion by 2025, emphasizing the importance of having filling machines that suit technological advancements and consumer demands.

**Tips:** When considering a filling machine, evaluate the nature of your product, including its viscosity, temperature, and sensitivity. This will significantly impact your machine selection process. Additionally, assess the filling speed and the level of automation you require, as these factors can greatly influence production efficiency and labor costs. Keeping these considerations in mind will help you choose a machine that aligns well with your operational goals.

Key Factors to Consider When Choosing a Filling Machine

When selecting a filling machine for your packaging needs, there are several key factors that must be considered to ensure optimal performance and efficiency. First and foremost, the type of product being filled plays a crucial role in determining the suitable machine. Different products, such as liquids, powders, or granules, require specific filling mechanisms to ensure precise and consistent volume. Assessing the viscosity, granule size, and flow characteristics of the product helps in selecting the right filling technology, be it gravitational, pressure, vacuum, or auger filling.

Another essential factor is the production speed required. Analyzing the expected output per hour can help in choosing a filling machine that meets operational goals without sacrificing accuracy. Additionally, the machine’s ability to integrate with existing production lines and its scalability for future demands should be evaluated. Moreover, ease of cleaning and maintenance is critical, especially for businesses that handle multiple products or adhere to strict hygiene standards. Opting for machines with quick-change features and modular designs can significantly reduce downtime and labor costs while enhancing overall productivity.

How to Choose the Right Filling Machine for Your Packaging Needs

| Filling Mechanism | Application | Fill Volume Range | Speed (Bottles per Minute) | Cost ($) | Ease of Cleaning |

|---|---|---|---|---|---|

| Piston Filling | Viscous liquids | 100 - 1000 ml | 30 | 5000 | Moderate |

| Gravity Filling | Water-like liquids | 50 - 500 ml | 50 | 3000 | Easy |

| Vacuum Filling | Foamy liquids | 100 - 1000 ml | 40 | 6000 | Challenging |

| Continuous Filling | Dry powders | 10 - 100 g | 60 | 8000 | Moderate |

| Auger Filling | Granular products | 100 - 1000 g | 30 | 7000 | Easy |

Assessing Your Product Characteristics for Optimal Filling Solutions

When selecting a filling machine for your packaging needs, one of the most crucial steps is assessing your product characteristics. Understanding the nature of your product—whether it is liquid, semi-liquid, powder, or granular—will significantly influence the type of filling machine you require. For instance, free-flowing liquids may necessitate a gravity-fed filling system, while thicker products could require a piston filler that can handle viscosity. This initial analysis helps in narrowing down the options and avoiding costly mistakes associated with mismatched equipment.

Another vital factor to consider is the product's sensitivity to temperature, pressure, or other environmental conditions. Some materials may need specific handling to maintain quality, such as avoiding exposure to air or light. Additionally, features like the required fill volume, container type, and compatibility with other packaging machinery will further refine your choices. By thoroughly evaluating these product characteristics, businesses can select a filling machine that not only meets their operational demands but also ensures the integrity and quality of their packaged products.

Evaluating Production Speed and Efficiency Requirements

Choosing a filling machine that aligns with your production speed and efficiency requirements is crucial for optimizing your packaging process. First, consider your production volume and how quickly you need to fill containers. A high-speed filling machine may be necessary for large-scale operations, while a slower machine could suffice for smaller batches. Understanding your output goals will help you identify the right equipment that can meet your demand without causing bottlenecks in your production line.

In addition to speed, evaluate the efficiency of the machine in terms of setup and changeover times. A machine that allows for quick adjustments will minimize downtime and enhance overall productivity. Look for features such as automatic calibration and easy-to-use interfaces that streamline operation. By prioritizing these aspects, you can ensure that your filling process remains smooth and adaptable to changing production needs, ultimately supporting your business's growth.

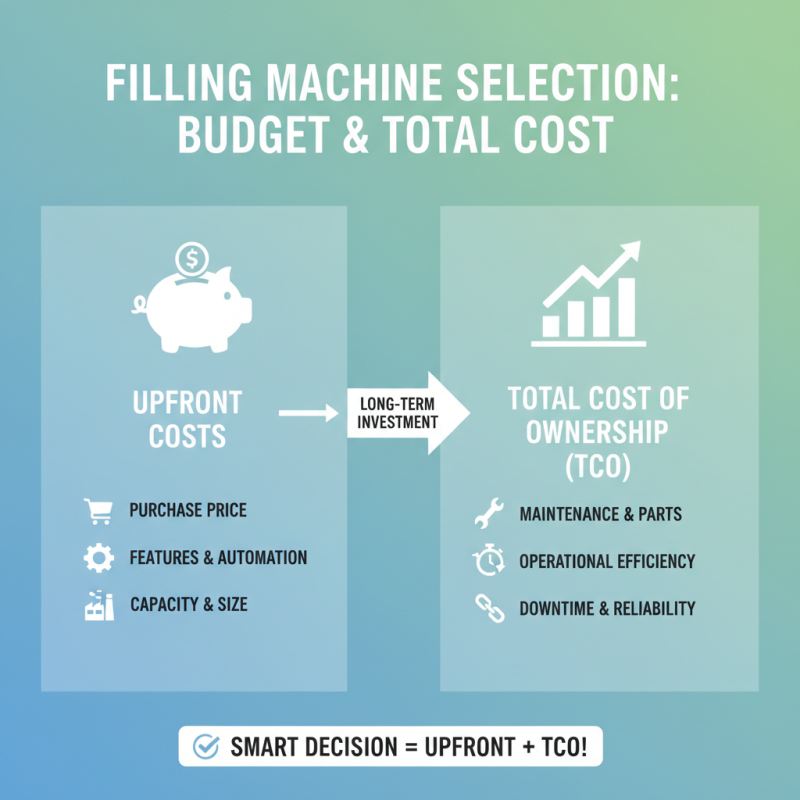

Budget Considerations and Total Cost of Ownership for Filling Equipment

When selecting a filling machine for your packaging needs, budget considerations and the total cost of ownership play a crucial role in the decision-making process. Initially, it’s important to assess the upfront costs, as the price of the machine itself can vary significantly based on features, automation levels, and capacities. However, focusing solely on the purchase price can be misleading. It’s essential to consider the long-term investment associated with maintenance, operational efficiencies, and potential downtime.

Moreover, the total cost of ownership encompasses various factors beyond the initial expenditure. Operational costs, including energy consumption, labor requirements, and the cost of materials used in conjunction with the machine, should also be evaluated. Additionally, the type and frequency of maintenance required can greatly affect ongoing expenses. Investing in a more efficient machine may have a higher initial cost but can result in significant savings over time through reduced labor, less waste, and decreased energy consumption. Thus, a comprehensive evaluation of both the budget and long-term costs will ensure that you choose a filling machine that meets your operational needs while remaining financially viable over its lifespan.

Related Posts

-

Top Automatic Packing Machines to Look for in 2025 for Efficient Packaging

-

Understanding Process Harvester Techniques for Effective Data Management

-

How to Choose the Right Automatic Packaging Machine for Your Business Needs

-

Top 7 Benefits of Using Fresh Harvester for Maximizing Fresh Produce Yields

-

Top 10 Benefits of Using an Automated Packaging Machine for Your Business

-

How to Choose the Right Box Packing Machine for Your Business Needs

A & B Packing Equipment

A&B has become the leader in fresh packing and cleaning equipment for fruits and vegetables worldwide. We have achieved this by relentlessly working to produce new and innovative ideas, along with the best customer service on Earth combined with hard working, dedicated, loyal employees and the latest industrial manufacturing techniques. We are now proud to say that we manufacture The Fulcrum Fresh Harvester, this is a one of a kind Berry Harvester that was specifically designed to handle fresh pick blueberries.

Contact Information

732 W. Saint Joseph Street

Lawrence, MI 49064

Phone: 269-539-4700 Fax: 269-539-4705

sale@industrialpackagingmachines.com