How to Choose the Right Pouch Filling Machine for Your Business?

Selecting the right pouch filling machine is crucial for your business success. According to industry expert John Smith, "A well-chosen pouch filling machine can boost production efficiency significantly." This insight highlights the importance of careful consideration during the selection process.

The market offers a variety of pouch filling machines, each with distinct features. Factors such as speed, size, and budget need attention. A high-speed machine may seem appealing, but it may not suit small businesses. Matching the machine’s capability with your production needs is essential.

Moreover, it’s important to consider not just the initial costs, but also long-term operational costs. Maintenance and training can add to your expenses. An effective pouch filling machine should enhance your production without leading to financial strain. Reflecting on these aspects can lead to better choices, ultimately contributing to your company's growth.

Understanding the Different Types of Pouch Filling Machines

When considering pouch filling machines, understanding different types is crucial. There are several options available for various industries. Some machines focus on liquid products, while others are made for powders or granules. Each type serves a unique purpose, and choosing the right one can be challenging.

For liquid filling, it’s essential to find a machine that ensures accurate measurements. Machines designed for powders often use augers and may struggle with thicker materials. Granule fillers can handle bulk products but may require frequent adjustments. Observing how these machines operate is vital. You may need to invest time to see what works best for your products.

Another consideration is the speed of production. Some machines operate quickly, but may compromise on precision. Others are slower but can maintain product integrity. It’s important to identify your needs before making a decision. Reflect on how production volume impacts your choice. Ultimately, weighing these factors can help determine the best option for your business.

Evaluating Your Business Needs for Pouch Filling Solutions

Choosing the right pouch filling machine is crucial for any business. It starts with a clear understanding of your specific needs. Evaluate factors like product type, packaging material, and production speed. A study by PMMI states that nearly 45% of manufacturers prioritize speed and efficiency in their filling processes. Identifying these needs early can prevent costly mistakes.

Consider the scale of operations. If your business is small, a semi-automatic machine might suffice. Larger operations may require fully automatic systems. Reports show that automatic machines can increase production efficiency by up to 30%. However, they often come with a higher initial cost. It's essential to analyze if this investment aligns with your business model.

Pay attention to the machine's flexibility. You may have different products to package. A one-size-fits-all approach might not work. Make sure the chosen machine can adapt to varying pouch sizes and materials. This adaptability can enhance your production line's efficiency and minimize waste. Ultimately, choosing wisely demands time and reflection on your unique business requirements.

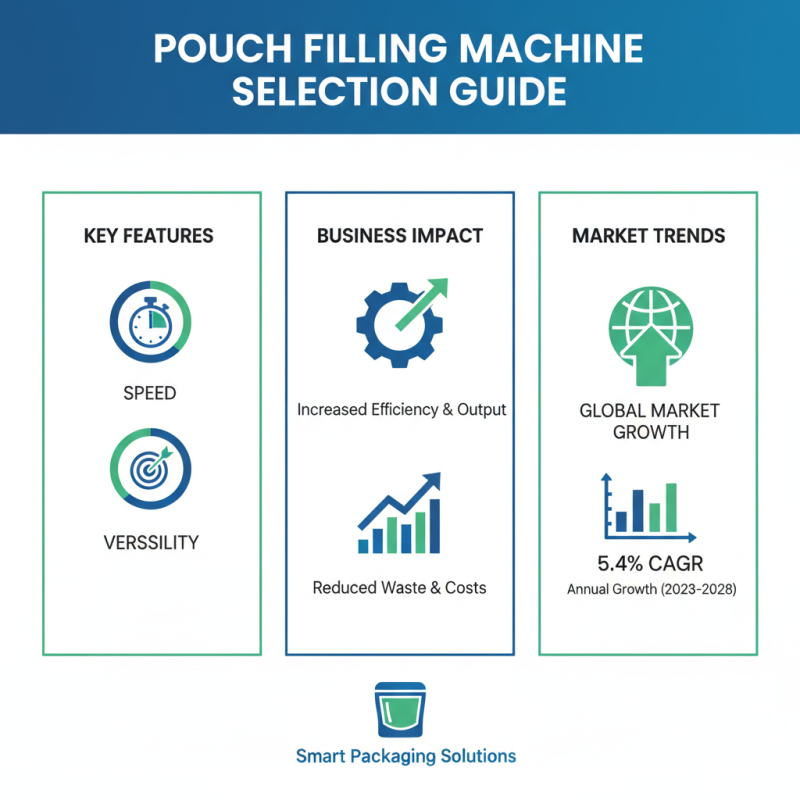

Key Features to Look for in Pouch Filling Equipment

Selecting the right pouch filling machine is vital for your business. When considering features, focus on speed, accuracy, and versatility. According to recent industry reports, the global pouch filling machinery market is expected to grow by 5.4% annually, reflecting increasing demand for efficient packaging solutions.

Key features to evaluate include the machine's filling speed. A machine that fills 30-60 pouches per minute may suit smaller operations. In contrast, larger operations might require machines that achieve 120 pouches per minute. Ensure the equipment can handle varying pouch sizes and materials. This flexibility can save costs in the long run.

Tips: Assess whether the machine offers easy size changeovers. Quick adjustments can minimize downtime. Also, look for a user-friendly interface. Complex controls can slow down operations. Ensure that maintenance is straightforward. Machines that are difficult to maintain can lead to productivity losses. Remember, a balance between advanced technology and simplicity is often ideal.

Budget Considerations When Choosing a Filling Machine

When considering a pouch filling machine, budget is crucial. The price range varies widely based on several factors. Automated machines often cost more than manual ones but can save on labor costs. While it may be tempting to opt for a cheaper model, high-quality machines can lead to fewer breakdowns and maintenance issues.

Think about the total cost of ownership. This includes installation, training, and maintenance. A low initial price might hide future expenses. Some machines may have hidden costs related to consumables or special parts. Evaluate how often you’ll need to repair or replace parts.

Don't forget about production needs. If your business scales, a small machine may become inadequate. It’s wise to consider future growth when setting a budget. Explore financing options if necessary. Reflecting on current and future needs can help you make a better decision.

Budget Considerations for Pouch Filling Machines

This chart illustrates the number of pouch filling machines available at different budget ranges. When selecting a filling machine, it's crucial to consider what is available within your budget to optimize your investment.

Comparing Manufacturer Options and Customer Support Availability

When selecting a pouch filling machine, one key factor is the manufacturer’s support. Many businesses overlook this aspect. However, customer support can directly impact production efficiency. A recent industry report highlighted that 74% of companies experienced downtime due to inadequate technical assistance. This statistic underscores the importance of having a reliable partner.

Evaluating support availability is crucial. Some manufacturers offer 24/7 support, while others provide limited hours. 42% of businesses shared that they encountered significant issues outside regular business hours. It's vital to consider how easily you can reach technical support when problems arise. Additionally, look for manufacturers that provide extensive training. This can reduce mistakes and improve operator confidence.

Not every manufacturer delivers the same level of service. Some may not even respond timely to inquiries. Ensure you test response times before committing. Explore testimonials and case studies as well. Real-world experiences often reveal gaps in support. Ultimately, your choice should balance machine quality and dependable customer service.

How to Choose the Right Pouch Filling Machine for Your Business? - Comparing Manufacturer Options and Customer Support Availability

| Manufacturer | Machine Model | Filling Speed (pouches/min) | Pouch Size (mm) | Support Availability | Warranty (years) |

|---|---|---|---|---|---|

| Manufacturer A | Model X1 | 40 | 100 - 200 | 24/7 Support | 2 |

| Manufacturer B | Model Y2 | 60 | 150 - 250 | Business Hours | 3 |

| Manufacturer C | Model Z3 | 50 | 120 - 220 | Online Chat | 1 |

| Manufacturer D | Model A4 | 70 | 130 - 230 | Email Support | 4 |

Related Posts

-

What is the Best Packaging Machine for Small Business Startups

-

How to Choose the Right Box Packing Machine for Your Business Needs

-

Top 10 Benefits of Using an Automated Packaging Machine for Your Business

-

2025 Top Trends in Fresh Harvester Technology and Innovations

-

How to Choose the Right Filling Machine for Your Packaging Needs

-

Top 7 Benefits of Using Fresh Harvester for Maximizing Fresh Produce Yields

A & B Packing Equipment

A&B has become the leader in fresh packing and cleaning equipment for fruits and vegetables worldwide. We have achieved this by relentlessly working to produce new and innovative ideas, along with the best customer service on Earth combined with hard working, dedicated, loyal employees and the latest industrial manufacturing techniques. We are now proud to say that we manufacture The Fulcrum Fresh Harvester, this is a one of a kind Berry Harvester that was specifically designed to handle fresh pick blueberries.

Contact Information

732 W. Saint Joseph Street

Lawrence, MI 49064

Phone: 269-539-4700 Fax: 269-539-4705

sale@industrialpackagingmachines.com