The Ultimate Guide to Choosing the Best Package Machine in 2025

As industries continue to evolve, the demand for efficient and innovative packaging solutions has never been higher. A recent report from the MarketsandMarkets research firm indicates that the global packaging machinery market is expected to reach $54.48 billion by 2025, growing at a compound annual growth rate (CAGR) of 4.9%. This trend underscores the importance of investing in the right package machine to enhance productivity and maintain competitiveness in the market.

According to Dr. Emily Johnson, an expert in packaging technology, “Choosing the right package machine is crucial for optimizing operational efficiency and meeting customer expectations.” Her insights highlight the complexities involved in selecting machinery that not only fits specific production needs but also adapts to rapidly changing consumer demands. As manufacturers look to future-proof their operations, understanding the various types of package machines and their functions becomes essential.

The year 2025 presents a pivotal moment for businesses aiming to maximize their output while minimizing waste and costs. This guide aims to navigate through the myriad of options available, providing valuable information that can aid in making informed decisions about the best package machine for diverse operational requirements.

Understanding the Different Types of Packaging Machines Available in 2025

When it comes to selecting the right packaging machine for your business in 2025, understanding the various types available is crucial to making an informed decision. Packaging machines can generally be classified into several categories, such as form-fill-seal machines, labeling machines, wrapping machines, and carton sealers. Each type serves a distinct purpose and is designed to handle specific packaging needs. For example, form-fill-seal machines are ideal for products that require both forming a package and filling it simultaneously, making them highly efficient for high-volume production.

Tips: When evaluating different types of packaging machines, consider your product specifications and production volume. This will help narrow down the options to those that best fit your operational requirements. Additionally, assess the versatility of the machine; a multi-functional machine can save both time and cost in the long run.

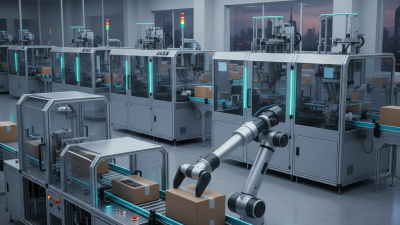

Moreover, automation is a key feature in modern packaging machines. Automated systems can significantly reduce labor costs and improve accuracy, making them a smart investment for businesses aiming to enhance productivity. However, ensure that your team is trained to operate and maintain these machines properly to avoid any potential downtime or operational issues.

Tips: Always check the machine’s compatibility with your current production line to ensure a seamless integration process. It's also beneficial to review user feedback and industry trends to stay ahead of the curve in your packaging strategy.

Key Features to Consider When Selecting a Packaging Machine

When selecting a packaging machine in 2025, understanding key features is crucial to ensuring that the chosen equipment meets specific operational needs. One of the first considerations is the machine's speed and efficiency, which plays a vital role in production capacity. It’s essential to evaluate the machine's ability to handle varying production volumes without sacrificing quality. Look for features that allow for quick changeovers between different product types or sizes, enabling flexibility in production lines.

Another important aspect is the machine's compatibility with different packaging materials. A versatile packaging machine should be able to work with various materials, from plastics to biodegradable options, catering to diverse product requirements and sustainability goals. Additionally, consider the automation level of the machine, as higher automation can reduce labor costs and increase consistency in packaging processes. Incorporating advanced technology, such as sensors and data analytics, can also enhance performance by providing real-time monitoring and insights into production efficiency.

Evaluating the Cost vs. Benefits of Various Packaging Solutions

When considering packaging solutions for your business in 2025, evaluating the cost versus benefits becomes crucial. Various packaging machines offer diverse features and efficiencies, impacting both your budget and operational capabilities. It’s essential to analyze not just the initial costs involved, but also the long-term savings and advantages they may provide. Look for machines that are energy-efficient and can adapt to various product sizes, which can significantly reduce overall operational costs.

Tips: Before committing to a specific packaging machine, assess the total cost of ownership. This includes maintenance expenses, energy consumption, and potential for automation integration. Such factors can often turn what appears to be a higher upfront cost into a more economical choice over time.

Furthermore, take the time to consider the flexibility and scalability of the packaging solutions. Machines that can adapt to changing production volumes or different product types are invaluable. Investing in a packaging machine that supports a range of packaging styles and materials may allow your business to pivot as market demands evolve, ultimately maximizing your return on investment.

The Ultimate Guide to Choosing the Best Package Machine in 2025 - Evaluating the Cost vs. Benefits of Various Packaging Solutions

| Packaging Type | Cost (Per Unit) | Production Speed (Units/Hour) | Material Used | Environmental Impact Rating |

|---|---|---|---|---|

| Manual Packaging | $0.50 | 20 | Plastic, Cardboard | Medium |

| Semi-Automatic Machine | $2.00 | 50 | Plastic, Biodegradable Film | Low |

| Fully Automatic Machine | $5.00 | 200 | Recyclable Materials | Very Low |

| Eco-Friendly Packaging Machine | $4.00 | 150 | Compostable Material | Minimal |

| Thermoform Packaging Machine | $3.50 | 100 | Plastic Film | High |

Top Brands and Models of Packaging Machines on the Market

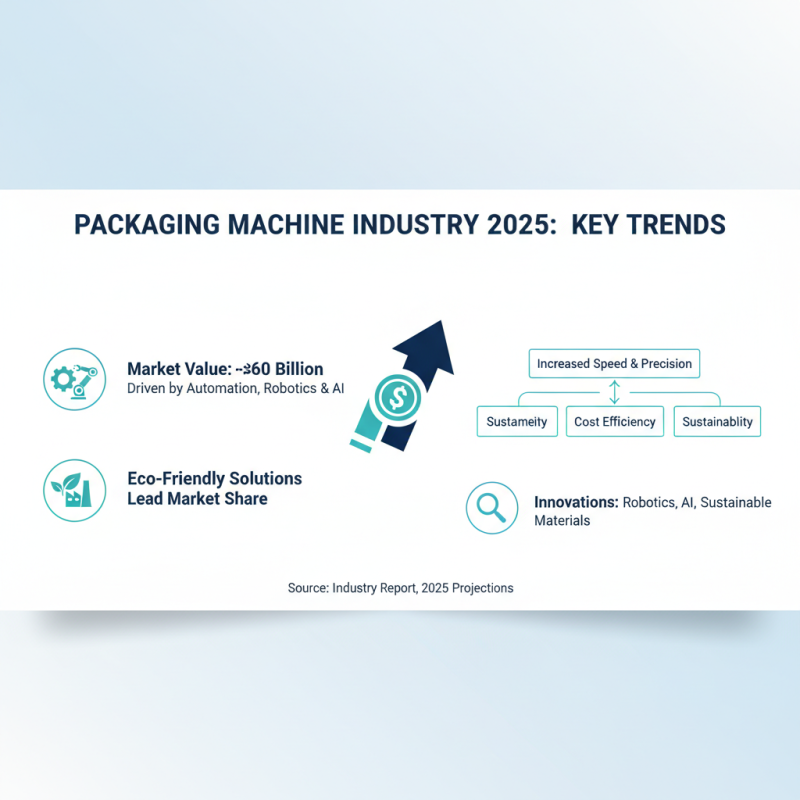

In 2025, the packaging machine industry is expected to reach a value of approximately $60 billion, driven by the increasing demand for automated solutions across various sectors. Within this bustling market, several top brands and models stand out due to their technological advancements and efficiency. For example, systems utilizing robotics and artificial intelligence are gaining traction, improving speed and precision in packaging processes. A recent report indicates that manufacturers focusing on eco-friendly packaging solutions are leading in market share, responding to consumer preferences for sustainability.

Prominent segments in the packaging machine market include horizontal form fill seal machines, vertical form fill seal machines, and labeling equipment. Reports highlight that horizontal form fill seal technology is projected to grow by over 8% annually, reflecting the rise in online shopping and the need for efficient packaging solutions that enhance shelf life and reduce spoilage. Additionally, advancements in smart packaging technology are driving innovation, as businesses seek to optimize their packaging lines to meet increasing production demands while minimizing waste. The integration of IoT in packaging machines is also set to transform operational practices, making real-time monitoring and data analytics a norm in the industry.

Future Trends in Packaging Technology to Watch For in 2025

As we look ahead to 2025, the packaging industry is set for groundbreaking transformations driven by technological advancements and sustainability goals. Emerging trends indicate a significant shift towards automation and smart packaging solutions that enhance efficiency while reducing waste. These innovations promise to revolutionize how products are packaged and delivered, ensuring that companies can meet the growing demands of eco-conscious consumers.

Tip: When considering packaging equipment, prioritize machines that offer adaptability to different product lines. Versatile machines can save time and costs as market demands shift and scaling operations becomes necessary.

Furthermore, sustainability will be at the forefront of packaging technology. Expect innovations in biodegradable materials and recyclable designs that not only meet regulatory standards but also resonate with environmentally aware customers. Companies that invest in these sustainable solutions will likely gain a competitive edge, as consumers increasingly favor products that align with their values.

Tip: Keep an eye on developments in packaging materials that reduce environmental impact. Research options such as plant-based plastics or lightweight materials that maintain product integrity without compromising ecological responsibility.

Related Posts

-

How to Choose the Right Automatic Packaging Machine for Your Business Needs

-

Top 10 Bagging Machines for Efficient Packaging Solutions and Cost Savings

-

How to Choose the Right Box Packing Machine for Your Business Needs

-

Why Choose a Bag Packing Machine for Your Packaging Needs?

-

Top 10 Benefits of Using an Automated Packaging Machine for Your Business

-

What is a Vegetable Packaging Machine and How Does it Benefit Your Business

A & B Packing Equipment

A&B has become the leader in fresh packing and cleaning equipment for fruits and vegetables worldwide. We have achieved this by relentlessly working to produce new and innovative ideas, along with the best customer service on Earth combined with hard working, dedicated, loyal employees and the latest industrial manufacturing techniques. We are now proud to say that we manufacture The Fulcrum Fresh Harvester, this is a one of a kind Berry Harvester that was specifically designed to handle fresh pick blueberries.

Contact Information

732 W. Saint Joseph Street

Lawrence, MI 49064

Phone: 269-539-4700 Fax: 269-539-4705

sale@industrialpackagingmachines.com