2026 Best Automated Packaging Solutions for Efficient Production?

In the fast-evolving industry of automated packaging, efficiency is key. Renowned expert Dr. Emily Carter, a leading figure in packaging technology, once stated, "Automated packaging solutions can revolutionize production lines by reducing waste and increasing speed." This sentiment rings true as businesses look for innovative ways to enhance their operations.

As we explore the 2026 best automated packaging solutions, it's essential to note that not all technologies deliver perfect results. Some systems may struggle with versatility or integration, prompting companies to reconsider their choices. Effective automated packaging should not only be fast but also adaptable to various products and materials.

Innovation in automated packaging is not without its challenges. Many companies invest heavily only to find their solutions lacking. The need for continuous improvement cannot be overstated. Technology evolves rapidly, and staying updated is crucial for maintaining a competitive edge in packaging. As we delve into this topic, let’s keep in mind both the accomplishments and the obstacles in the field of automated packaging.

Overview of Automated Packaging Solutions in 2026

Automated packaging solutions are evolving rapidly in 2026. According to recent industry reports, the global automated packaging market is expected to reach $45 billion by 2027, showing a significant annual growth rate. This increase is driven by the demand for efficiency and sustainability in production processes. Many manufacturers are investing in advanced robotics and AI technologies. They aim to optimize their packaging operations.

New data reveals that 54% of companies have implemented some form of automation in their packaging lines. This shift has resulted in faster production times and reduced labor costs. However, some challenges remain. Integration of new technologies can disrupt existing workflows. Employees may need retraining, which is often overlooked. Additionally, the upfront costs for automation technology can be high. Companies must weigh these risks against potential long-term savings.

Sustainability is another focus area. In 2026, about 37% of packaging solutions incorporate eco-friendly materials. However, not all companies are transitioning quickly enough. Many are hesitant to change due to initial costs and complexity. As consumer preferences shift towards sustainable products, those lagging behind may find themselves at a disadvantage. Balancing efficiency, cost, and sustainability is crucial for success in this evolving market.

2026 Best Automated Packaging Solutions for Efficient Production

| Solution Type | Key Features | Efficiency Gain (%) | Typical Application |

|---|---|---|---|

| Automated Case Erector | Fast setup, customizable sizes, integrated with conveyor | 40% | Food and Beverage |

| Robotic Palletizer | Multi-axis movement, high payload, vision systems | 60% | Consumer Goods |

| Shrink Wrapping Machine | Adjustable speed, user-friendly interface, energy efficient | 30% | Electronics |

| Filling Machine | Accurate dosing, automated cleaning, high speed | 45% | Pharmaceuticals |

| Labeling Machine | Precision labeling, multiple label formats, quick changeover | 25% | Health & Beauty |

Key Technologies Driving Efficiency in Packaging Automation

In the quest for efficient production, automation in packaging plays a vital role. Technologies such as robotics, artificial intelligence, and machine vision transform how products are packaged. These solutions reduce human error and increase speed. Robotic arms can perform repetitive tasks, handling packages swiftly. Machine vision ensures quality control, detecting defects early.

However, not every automated system is flawless. Some machines struggle with complex packaging shapes. Transitioning to automation can disrupt existing workflows. Training employees to adapt takes time and resources. As companies invest in new technologies, they must consider these challenges. Efficiency relies on both advanced machines and skilled operators to work together seamlessly.

Additionally, data analytics can optimize production lines. Analyzing performance helps identify bottlenecks. Yet, gathering and interpreting data requires expertise. Companies may face hurdles in effectively using data for improvement. Balancing technology with human insight is crucial for success in packaging automation.

2026 Best Automated Packaging Solutions for Efficient Production

Comparative Analysis of Automation Providers and Their Solutions

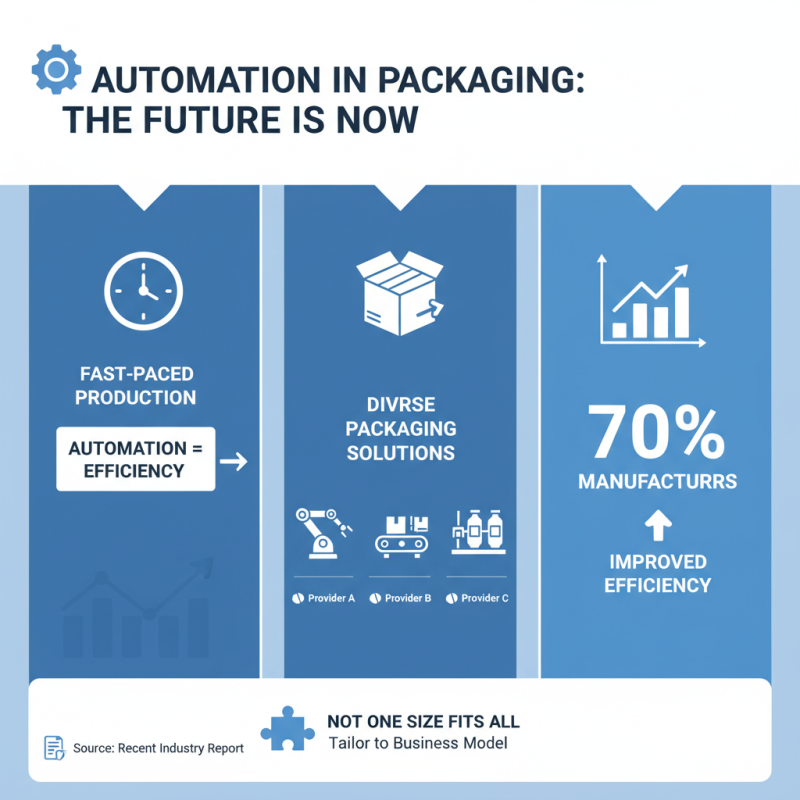

In today's fast-paced production landscape, automation is becoming key. Various providers offer distinct packaging solutions. A recent report reveals that 70% of manufacturers see improved efficiency through automation. However, not all solutions fit every business model.

For instance, some automation systems may require extensive training. This can lead to downtime during the transitional phase. A study indicated that organizations may experience up to 30% initial inefficiency as employees adapt to new technologies. On the other hand, integrating automated packaging can reduce labor costs by 25% in the long run.

Moreover, the variability in machine compatibility can pose challenges. Not all systems work seamlessly with existing infrastructure. A significant portion of companies reported compatibility issues impacting their productivity. Despite their advantages, these solutions must be carefully evaluated to align with specific operational needs. The data shows that a deeper understanding of each provider's offerings is crucial for effective implementation.

Case Studies: Successful Implementations of Automated Packaging

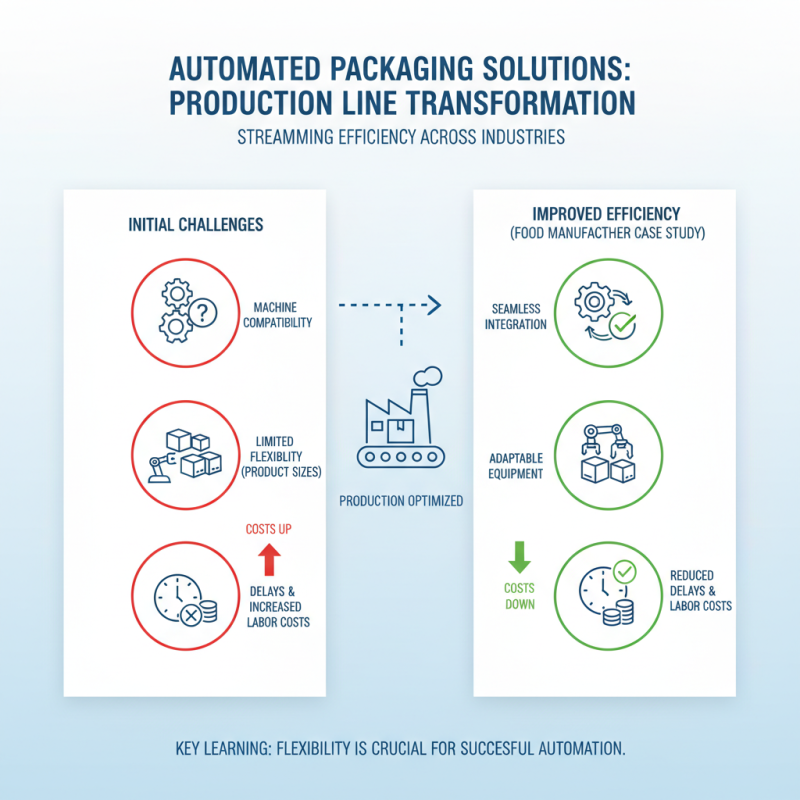

Automated packaging solutions have transformed production lines in various industries. Many companies have significantly improved efficiency by streamlining their packaging processes. One case study highlights a food manufacturer that integrated automated packing machines. Initially, they faced challenges with machine compatibility. Some equipment was not flexible enough to accommodate different product sizes. This led to delays and increased labor costs.

Another example features a cosmetics company. They adopted an automated system for their bottling and labeling processes. While initial results showed promise, they soon encountered problems with machine calibration. Inconsistent product flow caused some products to be mislabelled. The company learned the importance of regular maintenance and employee training. These insights were crucial in preventing future issues.

These case studies illustrate both successes and challenges in implementing automated packaging solutions. Companies must remain attentive to the intricacies of their systems. Automation can lead to great efficiency, but careful planning is essential. Balancing speed with accuracy requires ongoing adjustments and open communication among teams.

Future Trends and Innovations in Packaging Automation for Production

The future of packaging automation is bright and evolving. Various technologies are reshaping production lines. Robotics, for instance, allows precise handling of products. This reduces human error and speeds up processes. Smart sensors inform machines of inventory levels. They can adapt quickly to changing demands and avoid stockouts.

Moreover, artificial intelligence plays a crucial role. It predicts trends and optimizes layouts. This means less wasted space and energy. However, not all companies are ready for a full transition. Some struggle with the upfront costs and complexity. Others face workforce challenges as jobs shift to automation.

Investing in training is essential. Employees need skills to work alongside machines. Developing a balanced approach between man and machine is key. While innovations are exciting, caution is necessary. Overreliance on technology could lead to vulnerabilities in production. Maintaining a human touch in processes is vital.

Related Posts

-

Top Automatic Packing Machines to Look for in 2025 for Efficient Packaging

-

2025 How to Choose the Best Automatic Bag Filling Machine for Your Business

-

Why Choose a Bag Packing Machine for Your Packaging Needs?

-

How to Use a Process Harvester for Efficient Resource Management

-

2025 Top 5 Blueberry Harvesters with Industry Insights and Performance Analytics

-

How to Choose the Right Automatic Packaging Machine for Your Business Needs

A & B Packing Equipment

A&B has become the leader in fresh packing and cleaning equipment for fruits and vegetables worldwide. We have achieved this by relentlessly working to produce new and innovative ideas, along with the best customer service on Earth combined with hard working, dedicated, loyal employees and the latest industrial manufacturing techniques. We are now proud to say that we manufacture The Fulcrum Fresh Harvester, this is a one of a kind Berry Harvester that was specifically designed to handle fresh pick blueberries.

Contact Information

732 W. Saint Joseph Street

Lawrence, MI 49064

Phone: 269-539-4700 Fax: 269-539-4705

sale@industrialpackagingmachines.com